The Mule rides again (sort of) - pics.

Moderators: The Dark Side of Will, Series8217

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Spiffy rust repair on an old Porsche, mentions Wurth undercoating

http://forums.corner-carvers.com/showpo ... ostcount=6

http://forums.corner-carvers.com/showpo ... ostcount=6

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

The Dark Side of Will wrote:

Note to self: Even when buying Aurora rod ends, spend the extra money for the HD units. The CM's are loose out of the box. Basically .001 or so perceptible play, but zero rotation torque... I suspect these will need to be replaced with higher end units after relatively little drive time.

Forgot:

5/8-18 jam nuts

Sleeves to adapt 5/8" rod ends to 12mm bolt

(McMaster 2868T11 looks likely)

(McMaster 89955K579 also looks likely)

Design dimensions: OD: 0.625, ID (tight) clearance for 0.472, Length 0.750 +.000/-.010

The CM10's are $17 each

The AM10's are $42 each

The XAM8's are $46 each (These have 5/8-18 shank with 1/2" hole in the ball, and would require additional spacing to clamp the pivot tube)

Shown above is a 180 degree bend of 1" tube on a 3" radius. I finally took a few minutes to sketch the ball joint plate. I may not be able to get the ball joint far enough aft to recover the caster I lost without bringing it so far inboard that the outer edge of the bend hits the knuckle at full droop.

http://www.mandrel-bends.com/catalog/1- ... d-496.html

However, there is also a 180 degree 1.25" bend on a 3.75" radius which should allow that, as well as more clearance between the legs of the bend and the sides of the crossmember when adjusting caster. They'll need 0.75" of additional spacing between the pivot tube on the crossmember and the rod ends, but that's fairly easy; such spacers can be made with shoulders in order to help keep everything aligned.

http://www.mandrel-bends.com/catalog/1- ... d-564.html

I think I'll have to make the 5/8" rod end adapters for the 1.25" tube, though.

These might work, but are really made for thicker wall tubing than I linked above: http://secure.chassisshop.com/partdetail/C73-940-2/

I'll try the 1" tube units first to see how well they work (Or don't) before I try the 1.25" tube. These parts are so cheap I'll be able to make 3-4 prototypes before I'll feel guilty about screwing things up.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

The Dark Side of Will wrote:Had a conversation with an engineer at New Hampshire Ball Bearing today

http://www.nhbb.com

While I would really like to find an auto industry spherical bearing small enough to use in the Fiero's bushings locations, it doesn't look like that's going to work out.

NHBB part numbers ADW10VN or ADW10VNL would be what I'd want to use. The L stands for a difference in liner systems which has no impact on load performance.

This is the "wide" version. I went with it for improved service life and lower contact pressure during impact loading scenarios compared with the narrow version.

Those are sealed spherical bearings.

The unsealed versions end up with 8-10 inch lbs of preload torque, while the sealed versions can have 20 inlbs or more of preload

There's a version with subtle chamfers on the corners of the housing, and it's typically used with snap rings

However, sometimes the V-grooved version--intended for a staked installation--is preferred in order to have better contact with snap rings.

The OD of the bearing is spec'd as: 1.1870-1.1875

So the ID of the bore should be: 1.1873-1.1878

This results in .0002 press to .0008 clearance fit

Some customers go to a .0005 press, although that drives preload torque up (not a big concern for this application)

Catalog available here:

http://nhbb.com/files/catalog_pages/NHB ... g-2014.pdf

My particular part is on page marked 11.

Pgs 52-88/89 cover fairly serious engineering data

Hendrick Motorsports is a customer with whom the engineer had dealt before.

I *MAY* have just had a stroke of genius which allows me to use standard spherical bearings in suspension applications...

<Ahem> "Motorcycle brake caliper piston dust boots"

e.g.: http://www.amazon.com/Motorcycle-Dust-F ... B009019L0K

I need to do some looking to make sure I can get something with an ID of ~19mm and OD of ~30-31mm

That is all.

EDIT:

http://www.franklinkart.com/cgi-bin/com ... 086919.HP4

http://italianmotorsusa.myshopify.com/c ... eal-5-pack (Why the fuck do they sell caliper seals in packs of FIVE?!)

(probably for 19mm master cylinder...) http://www.fastech-racing.com/birel-fre ... 87.20.html

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

May not be able to find the right product quickly, so I'm going to move forward with getting shells made to accept concentric shaft seals. i'll get a set made for the rear of The Mule ('87) and the front of the Storm Trooper ('88), and by then I might have found something that will work for the '84-'87 front.The Dark Side of Will wrote: I *MAY* have just had a stroke of genius which allows me to use standard spherical bearings in suspension applications...

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

The plate is 5/32", which is plenty thick considering that the stock control arm is ~0.100 where the ball joint bolts on.

The plate will be tacked in this week.

Next step will be to dig up (or, heaven forbid, BUY) a ball joint to test fit with stock and Street Dreams knuckles. If I'm lucky, the ball joint will run out of travel before the arm hits the knuckle. After that, I need to do a trial assembly with my extra crossmember to make sure that the suspension works through the full range of motion.

The ball joint mounting surface on the stock crossmember is inclined inward compared to mine (or mine is tilted outward compared to stock). This means that the ball joint is closer to its angular limit in droop and I may not have the full droop travel available. Also, hitting the end of its travel like that isn't kind to the balljoint. The control arms are WAY easier to make this way than with that angle incorporated. This way the same part can be used on both sides; if I did it like stock, I'd have to have two different parts. If it works, great, if it doesn't I'll come up with something better.

If the ball joint location is off-center but the plate is flat OR if the ball joint is centered but the plate is angled, I can get by with one part for both sides.

If the plate is angled but the ball joint is centered, I'll need a good bit more caster adjustment, but I can probably get that done via one of the methods I discussed a couple of posts above.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Spare parts mockup. The control arm is on top of the ball joint in order to clear the Street Dreams knuckle (not pictured) at full ball joint angle.

I hadn't noticed this before, but there's a droop limiting feature on the crossmember which interacts with the stock control arm.

Because the feature on the stock control arm that this droop limiter touches is ABOVE the pivot axis, these control arms will give up some droop travel relative to stock. I don't know exactly how much this translates to at the wheel... I'll have to measure it.

Also, the rear leg of the control arm is VERY close to the side of the crossmember.

Also note that the rod ends are threaded pretty far out... I haven't measured engagement, but it's probably beyond the generally accepted "safe" limit of thread engagement depth equal to the thread diameter.

Mostly because of how close the rear leg is to the side of the crossmember, but also because of the droop limiter, I'll go ahead and switch to the larger radius bends. A larger bend radius will increase the separation between the legs of the control arm. This will also push the rod end fittings closer to the pivot by the difference in bend radius, which helps thread engagement.

My initial idea was that camber would be adjusted by threading the rod ends in or out the same direction, while caster would be changed by differential adjustment.

If I go to the larger radius bend, then I can ALSO adjust caster by moving the spacers between the rod ends and the crossmember, similar to the way it's done stock. Between the spacers/shims and differential rod-end adjustment, there should be PLENTY of capability

I hadn't noticed this before, but there's a droop limiting feature on the crossmember which interacts with the stock control arm.

Because the feature on the stock control arm that this droop limiter touches is ABOVE the pivot axis, these control arms will give up some droop travel relative to stock. I don't know exactly how much this translates to at the wheel... I'll have to measure it.

Also, the rear leg of the control arm is VERY close to the side of the crossmember.

Also note that the rod ends are threaded pretty far out... I haven't measured engagement, but it's probably beyond the generally accepted "safe" limit of thread engagement depth equal to the thread diameter.

Mostly because of how close the rear leg is to the side of the crossmember, but also because of the droop limiter, I'll go ahead and switch to the larger radius bends. A larger bend radius will increase the separation between the legs of the control arm. This will also push the rod end fittings closer to the pivot by the difference in bend radius, which helps thread engagement.

My initial idea was that camber would be adjusted by threading the rod ends in or out the same direction, while caster would be changed by differential adjustment.

If I go to the larger radius bend, then I can ALSO adjust caster by moving the spacers between the rod ends and the crossmember, similar to the way it's done stock. Between the spacers/shims and differential rod-end adjustment, there should be PLENTY of capability

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

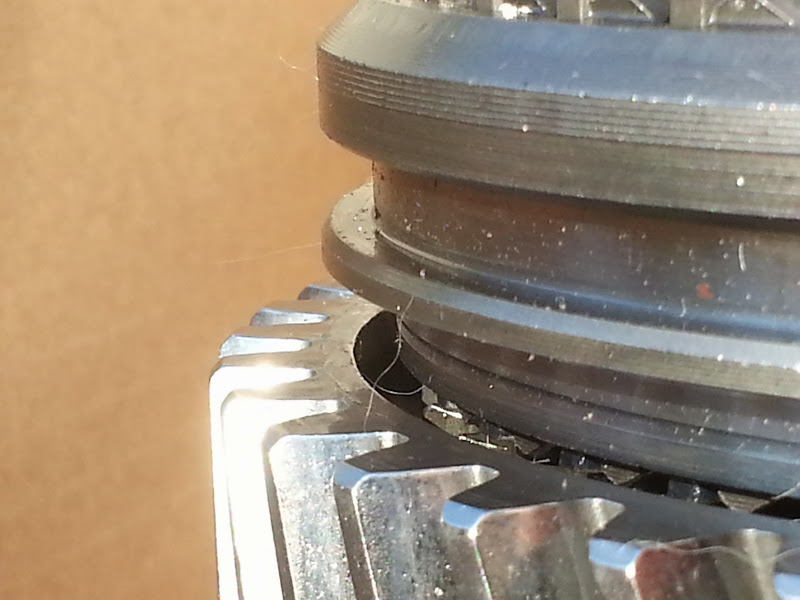

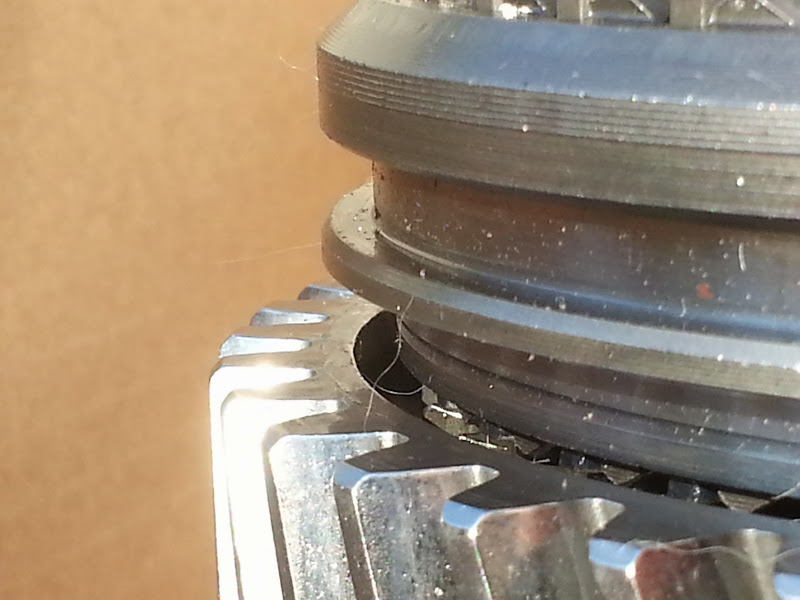

Reminder: Getrag 282 1-2 synchro hubs; the SHALLOW/THIN shoulder goes toward FIRST gear.

Also, the circumferentially grooved side of the shift collar goes toward first.

Also, the circumferentially grooved side of the shift collar goes toward first.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

This is how Houseman modified the 1-2 shift collar to fit inside the smaller 1st output gear:

However, on inspection of the assembly, it's evident that it doesn't have to be cut back that much:

Note the radial clearance between the ID of the gear and the modified OD of the shift collar.

The ID of the gear is tapered, so considered modification of a virgin shift collar would leave it tapered as well. It might not be much larger in diameter or have a much thicker wall at the distal end, but it will have a much thicker wall at the proximal end.

I'm not so concerned about the radial thickness of the shift collar where the teeth engage the gear as I am about the thin "wall" that takes load from the shift fork when I'm hammering it down into first for a slow corner. I'm going to have one of my dad's friends radius the visible edge of the gear and machine an extra shift collar I have hanging around with a radius under the edge of the "wall".

And fully seated:

However, on inspection of the assembly, it's evident that it doesn't have to be cut back that much:

Note the radial clearance between the ID of the gear and the modified OD of the shift collar.

The ID of the gear is tapered, so considered modification of a virgin shift collar would leave it tapered as well. It might not be much larger in diameter or have a much thicker wall at the distal end, but it will have a much thicker wall at the proximal end.

I'm not so concerned about the radial thickness of the shift collar where the teeth engage the gear as I am about the thin "wall" that takes load from the shift fork when I'm hammering it down into first for a slow corner. I'm going to have one of my dad's friends radius the visible edge of the gear and machine an extra shift collar I have hanging around with a radius under the edge of the "wall".

And fully seated:

- Shaun41178(2)

- Posts: 8368

- Joined: Fri Nov 19, 2004 7:12 pm

- Location: Ben Phelps is an alleged scammer

Re: The Mule rides again (sort of) - pics.

Any trans updates?

FieroPhrek working on that ls4 swap for 18 years and counting now. 18 years!!!!! LOL

530 whp is greater than 312

530 whp is greater than 312

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Machinist modded the second collar... There was a miscommunication because it's not what I wanted... but will work. It needs a smidge more touching up, though. I'm not sure if I have another easily accessible shift collar around to modify.

- Series8217

- 1988 Fiero Track Car

- Posts: 5978

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: The Mule rides again (sort of) - pics.

You could call WCF; I gave them all my spare Getrag parts. Bins of parts. Might need to just e-mail them a photo to see if they can match it.The Dark Side of Will wrote:Machinist modded the second collar... There was a miscommunication because it's not what I wanted... but will work. It needs a smidge more touching up, though. I'm not sure if I have another easily accessible shift collar around to modify.

Re: The Mule rides again (sort of) - pics.

I have a disassembled Getrag for parts Will, shoot me exactly what you need and I will see if that part is any good and you can have it.

-

ericjon262

- Posts: 2824

- Joined: Mon May 24, 2010 5:34 pm

- Location: Aiken, SC

Re: The Mule rides again (sort of) - pics.

Billet?

http://www.ebay.com/itm/AURORA-V8-Bryan ... 0970060850

Keep in mind, that price is for the whole pallet of 16 cranks, he says in the add he might separate one. one of them is also 180*!

http://www.ebay.com/itm/AURORA-V8-Bryan ... 0970060850

Keep in mind, that price is for the whole pallet of 16 cranks, he says in the add he might separate one. one of them is also 180*!

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

- Series8217

- 1988 Fiero Track Car

- Posts: 5978

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: The Mule rides again (sort of) - pics.

That's for the IRL motor. Completely different than the N*/Aurora we know.ericjon262 wrote:Billet?

http://www.ebay.com/itm/AURORA-V8-Bryan ... 0970060850

Keep in mind, that price is for the whole pallet of 16 cranks, he says in the add he might separate one. one of them is also 180*!

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

I don't know how the bore centers (or main bearing widths) of the IRL engines compare with those dimensions on the productions engines. If they're different, these cranks certainly will not fit. If they're the same, the cranks might be workable.ericjon262 wrote:Billet?

http://www.ebay.com/itm/AURORA-V8-Bryan ... 0970060850

Keep in mind, that price is for the whole pallet of 16 cranks, he says in the add he might separate one. one of them is also 180*!

He lists the main journal diameters of these cranks as 2.467", while the production main journals are 64mm (2.520")

Also, the Northstar has head flow comaparable to that of an LS1, but way less displacement. This means it already needs to rev high to make power. It's also fully capable of turning 8500 RPM with aftermarket rods and pistons on the production stroke cast crank. It does NOT need to have a reduced stroke and less displacement, which would only require it to rev higher and be in a less civilized state of tune on the street.

Yes, a billet 180 degree crank is an intriguing piece of work. I'll take mine with stock stroke, though.

A billet crank also requires custom billet cams with the appropriate firing order. Those are going to be at least as expensive as the crank itself, FYI.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

PM'djelly2m81 wrote:I have a disassembled Getrag for parts Will, shoot me exactly what you need and I will see if that part is any good and you can have it.

Re: The Mule rides again (sort of) - pics.

Just to be sure, it's part #43 correct?

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Correct.

Thanks!

Do I need to buy you a beer now?

Thanks!

Do I need to buy you a beer now?

Re: The Mule rides again (sort of) - pics.

Yeah, you do. That's not a fun part to get off.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15626

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Only if you haven't already broken the cluster down. All I had to do to get to the one I had modified was cut two zip ties.

I strongly suspect that the transmission which originally contained the part Jelly is offering is already a pile of components on a shelf somewhere.

If I'm wrong, I really owe him a good beer, though!

I strongly suspect that the transmission which originally contained the part Jelly is offering is already a pile of components on a shelf somewhere.

If I'm wrong, I really owe him a good beer, though!