Spherical bearing upper strut mounts

Moderators: The Dark Side of Will, Series8217

- Series8217

- 1988 Fiero Track Car

- Posts: 5974

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Spherical bearing upper strut mounts

Has anyone built spherical bearing upper strut mounts for a Fiero, and still have the drawings?

I just added some thrust bearings and Hyperco helper springs to my coilovers, but now I need to tackle the upper mount. I'm currently just using the stock 88 top hat and mount; it doesn't even provide a flat surface for the spring, let alone allow the spring to pivot with the strut. I hear (and feel) a lot of binding.

I'd like to build a nice upper mount so my setup resembles these: http://farnorthracing.com/autocross/konis.html

If nobody else has the drawings I'll whip some up in a couple weeks.

I just added some thrust bearings and Hyperco helper springs to my coilovers, but now I need to tackle the upper mount. I'm currently just using the stock 88 top hat and mount; it doesn't even provide a flat surface for the spring, let alone allow the spring to pivot with the strut. I hear (and feel) a lot of binding.

I'd like to build a nice upper mount so my setup resembles these: http://farnorthracing.com/autocross/konis.html

If nobody else has the drawings I'll whip some up in a couple weeks.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15618

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Spherical bearing upper strut mounts

I used spherical bearings for the strut shafts in that Fierorrari I worked on a while back, but they only took the damper loads, not the spring loads. Far North at least mentions the load capacity, but I'd be hesitant about putting spring loads through a spherical bearing axially.

What binding are you feeling? The original rubber mounts are definitely going to be gooey and unpredictable as a suspension with cornering loads goes through its travel, however, I would expect that the spring would be "springy" rather than "binding" as the strut top angle changes.

What binding are you feeling? The original rubber mounts are definitely going to be gooey and unpredictable as a suspension with cornering loads goes through its travel, however, I would expect that the spring would be "springy" rather than "binding" as the strut top angle changes.

- Series8217

- 1988 Fiero Track Car

- Posts: 5974

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: Spherical bearing upper strut mounts

Spring load already goes through the spherical bearing on any MacPherson strut car with steering (i.e. not the Fiero) doesn't it? The springs have to turn with the wheels.. or do they just have a thrust bearing up top that spins against the strut tower?

I do need to at least make some flat top hats at least. My springs are getting tweaked because they don't have a flat surface to sit on (my top hats are upside down).

It felt jarring over some bumps and I heard some twangs and/or bangs. I stuck some thrust bearings on my perches and finally drove the car a couple hours ago. Binding seems to be gone or reduced.What binding are you feeling? The original rubber mounts are definitely going to be gooey and unpredictable as a suspension with cornering loads goes through its travel, however, I would expect that the spring would be "springy" rather than "binding" as the strut top angle changes.

I do need to at least make some flat top hats at least. My springs are getting tweaked because they don't have a flat surface to sit on (my top hats are upside down).

- Series8217

- 1988 Fiero Track Car

- Posts: 5974

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: Spherical bearing upper strut mounts

Here are the specs on the spherical bearing that Dennis Grant (Far North Racing) recommends:

http://cad.aurorabearing.com/item/roduc ... 76|3001313

http://cad.aurorabearing.com/item/roduc ... 76|3001313

-

The Dark Side of Will

- Peer Mediator

- Posts: 15618

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Spherical bearing upper strut mounts

Yes, an anti-friction thrust bearing is common practice in strut suspensions that steer. Even the GOOOSE had ball bearings built into the top assembly of the strut.Series8217 wrote:Spring load already goes through the spherical bearing on any MacPherson strut car with steering (i.e. not the Fiero) doesn't it? The springs have to turn with the wheels.. or do they just have a thrust bearing up top that spins against the strut tower?

It felt jarring over some bumps and I heard some twangs and/or bangs. I stuck some thrust bearings on my perches and finally drove the car a couple hours ago. Binding seems to be gone or reduced.

I do need to at least make some flat top hats at least. My springs are getting tweaked because they don't have a flat surface to sit on (my top hats are upside down).

My top-hats are in the original orientation and my car's only lowered about an inch in the rear, but I hadn't noticed such behavior. I suspect you'd just need a feature on the bottom of the top-hat to locate the spring.

A 325iX guy at www.e30tech.com installed Ground Control camber plates on his car and said that he gained noticeable handing precision after removing the rubber top mount at the strut. I can also see that without the rubber flexing, the dampers (especially extremely stiff dampers especially) can react more quickly to suspension motion.

Re: Spherical bearing upper strut mounts

Would something like this work? http://www.hypercoils.com/spring-perches.html

-

The Dark Side of Will

- Peer Mediator

- Posts: 15618

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Spherical bearing upper strut mounts

Interesting...eHoward wrote:Would something like this work? http://www.hypercoils.com/spring-perches.html

- Series8217

- 1988 Fiero Track Car

- Posts: 5974

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: Spherical bearing upper strut mounts

I saw those mentioned on Dennis Grant's site. They may work if they allow enough angular displacement (they allow 4deg; not sure how much is needed yet), but I don't know if they're really designed to be used in lieu of a spherical upper mount.eHoward wrote:Would something like this work? http://www.hypercoils.com/spring-perches.html

The problem with those is they're about $200 each and need to be rebuilt regularly.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15618

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Spherical bearing upper strut mounts

Also, how much of a problem *IS* off-axis loading from the spring? Is it a problem at all? How much is the frictional spring loading on the strut compared to the cornering loads on the struts? I think that product is designed with conventional dual-heim dampers in mind, and those aren't designed to take bending loads, while struts ARE designed for bending loads.

- Series8217

- 1988 Fiero Track Car

- Posts: 5974

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: Spherical bearing upper strut mounts

Just because the struts are designed to take the bending loads doesn't mean that their performance can't be improved by eliminating or reducing those loads.The Dark Side of Will wrote:Also, how much of a problem *IS* off-axis loading from the spring? Is it a problem at all? How much is the frictional spring loading on the strut compared to the cornering loads on the struts? I think that product is designed with conventional dual-heim dampers in mind, and those aren't designed to take bending loads, while struts ARE designed for bending loads.

I was reading an unrelated article today about the old Praxis air spring suspension for the WRX, and happened across some very interesting information on strut bending loads. The article points out that factory strut systems do NOT place the spring axis parallel to the strut axis. They actually offset it to counteract the bending moment created by wheel force:

Bridgestone's tests showed a conventional WRX coil-over, with the spring in line with the strut, had about 250 pounds of binding force pushing sideways on the middle of the strut. Depending on the frictional characteristics of the strut bearings and piston, this could mean about 30 or 40 pounds of static friction that has to be overcome before the strut can begin to move.

Angling the spring toward the centerline of the tire pushes on the strut in the opposite direction, reducing or even completely canceling this binding force. The stock Subaru strut, for example, only has 60 pounds of binding force. The shape of the air spring gives a little more mounting flexibility than a coil spring, so it was able to be mounted at an even steeper angle, completely eliminating this binding force.

Read more: http://www.modified.com/roadtests/0311_ ... z29bKFvHAf

-

FieroWanaBe1

- Posts: 427

- Joined: Sun Mar 11, 2007 11:26 pm

Re: Spherical bearing upper strut mounts

I dont see the farnorthdesign as more robust than the status qou. I would not like to have the single pillow spherical loaded entirly by damping and some cornering forces with the now added spring force. (it makes it easier to replace the bearings though, as there is no thrust bearing to service now.) A nice by-product of the inclined strut axis, is as the spring is compressed off axis, the induced moment can counter the shaft load from conering. If it is designed too, I would have to take a closer look, no time right now (im thinking it works against the favorable to be honest). If there is a strong control of the materials and material properties of the bearing and race, I would be more accepting of the singple point load design.Im not a fan of the sanp ring retention for the sleeves as well, machining the koni shock, which wasnt designed to have such a stress riser on its shell is introducing a new potential failure point, something I always try to eliminate if possible.

At minimum rating I would consider this, simply using a 4g load of total vehicle weight as a very unsunstantiaded approximation of shock load.

http://www.mcmaster.com/#2459K13

Also, placing the spring centerline and the strut motion axis oblique is common practice (not always though). Look at the factory fiero strut, it is built in the same manner.

At minimum rating I would consider this, simply using a 4g load of total vehicle weight as a very unsunstantiaded approximation of shock load.

http://www.mcmaster.com/#2459K13

Also, placing the spring centerline and the strut motion axis oblique is common practice (not always though). Look at the factory fiero strut, it is built in the same manner.

car.

- Series8217

- 1988 Fiero Track Car

- Posts: 5974

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: Spherical bearing upper strut mounts

If the "status quo" is motorsport racing struts, they all place the spring and damping forces on the spherical upper bearing, so I'm not sure what you are saying. DG's design is just an adaptation of those designs to a DSM using Koni yellows.

AST:

Penske:

Moton:

AST:

Penske:

Moton:

-

FieroWanaBe1

- Posts: 427

- Joined: Sun Mar 11, 2007 11:26 pm

Re: Spherical bearing upper strut mounts

I was refering to most OE designs.

I do see the merit in a single load point from a service standpoint on the race track.

I do see the merit in a single load point from a service standpoint on the race track.

car.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15618

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Spherical bearing upper strut mounts

I'd be looking at something like that also... BUT, you'd need two of them back-to-back to keep the suspension from coming apart in droop.FieroWanaBe1 wrote: At minimum rating I would consider this, simply using a 4g load of total vehicle weight as a very unsunstantiaded approximation of shock load.

http://www.mcmaster.com/#2459K13

-

FieroWanaBe1

- Posts: 427

- Joined: Sun Mar 11, 2007 11:26 pm

Re: Spherical bearing upper strut mounts

Thats hoping the arc of travel is transversal when installed back to back. If the unit is installed with preload even at full droop two units back to back are unecessary, as the bearing is almost always loaded in the proper direction.The Dark Side of Will wrote:I'd be looking at something like that also... BUT, you'd need two of them back-to-back to keep the suspension from coming apart in droop.FieroWanaBe1 wrote: At minimum rating I would consider this, simply using a 4g load of total vehicle weight as a very unsunstantiaded approximation of shock load.

http://www.mcmaster.com/#2459K13

car.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15618

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Spherical bearing upper strut mounts

Preload at full droop isn't relevant.

The upper spring seat will be retained on the strut shaft by the top nut. The spring will push against the lower face of the spring seat, while the upper face of the spring seat will mount the convex side of that spherical bearing. The concave side would be mounted to the body. There's nothing to prevent that bearing from coming apart once weight is off the wheels.

There will have to be a spacer between the two convex parts to make it an actual *spherical* bearing rather than an elliptical bearing with spherical faces (which wouldn't work...). That spacer could be a very stiff spring to double as a bump stop, too...

Also, you can't count on preload at full droop.

If you have 400# springs and 650# of sprung weight (750# corner weight less 100# of unsprung weight) and 2" of droop travel, there won't be preload at full droop. Also, the lower the static ride height, the greater the droop travel is...

The upper spring seat will be retained on the strut shaft by the top nut. The spring will push against the lower face of the spring seat, while the upper face of the spring seat will mount the convex side of that spherical bearing. The concave side would be mounted to the body. There's nothing to prevent that bearing from coming apart once weight is off the wheels.

There will have to be a spacer between the two convex parts to make it an actual *spherical* bearing rather than an elliptical bearing with spherical faces (which wouldn't work...). That spacer could be a very stiff spring to double as a bump stop, too...

Also, you can't count on preload at full droop.

If you have 400# springs and 650# of sprung weight (750# corner weight less 100# of unsprung weight) and 2" of droop travel, there won't be preload at full droop. Also, the lower the static ride height, the greater the droop travel is...

-

The Dark Side of Will

- Peer Mediator

- Posts: 15618

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Spherical bearing upper strut mounts

I'd forgotten about that Praxis setup... I guess it wasn't as big a thing as they wanted it to be, or I'd hear more about it.Series8217 wrote:Just because the struts are designed to take the bending loads doesn't mean that their performance can't be improved by eliminating or reducing those loads.The Dark Side of Will wrote:Also, how much of a problem *IS* off-axis loading from the spring? Is it a problem at all? How much is the frictional spring loading on the strut compared to the cornering loads on the struts? I think that product is designed with conventional dual-heim dampers in mind, and those aren't designed to take bending loads, while struts ARE designed for bending loads.

I was reading an unrelated article today about the old Praxis air spring suspension for the WRX, and happened across some very interesting information on strut bending loads. The article points out that factory strut systems do NOT place the spring axis parallel to the strut axis. They actually offset it to counteract the bending moment created by wheel force:Bridgestone's tests showed a conventional WRX coil-over, with the spring in line with the strut, had about 250 pounds of binding force pushing sideways on the middle of the strut. Depending on the frictional characteristics of the strut bearings and piston, this could mean about 30 or 40 pounds of static friction that has to be overcome before the strut can begin to move.

Angling the spring toward the centerline of the tire pushes on the strut in the opposite direction, reducing or even completely canceling this binding force. The stock Subaru strut, for example, only has 60 pounds of binding force. The shape of the air spring gives a little more mounting flexibility than a coil spring, so it was able to be mounted at an even steeper angle, completely eliminating this binding force.

Read more: http://www.modified.com/roadtests/0311_ ... z29bKFvHAf

Static friction isn't desirable at all, and if you can make a minor design adjustment to get rid of it, why not?

However, if getting rid of it entails a significant effort or expense, the payoff should definitely be understood.

30 to 40 pounds of static friction doesn't seem like much... that's only 0.3-0.4 g's of wheel acceleration on 100# of unsprung weight. A big deal in a Formula Atlantic? You bet. A big deal in a WRX? I think there's MUCH lower hanging fruit to pursue.

What I was alluding to was that the internal construction of a strut vs. a dual heim damper can have a big effect on the translation of bending moment into static friction. The design requirements of a strut bias it toward a design that does not allow bending loads to become static friction, while the design requirements of a dual heim damper do not necessarily favor that.

The primary design feature I'm thinking of here is the placement of the top and bottom guides to maximize the distance between them. That seems like a "normal thing to do" for any damper, but requirements drive the design toward maximizing this distance in a strut, while for a dual heim damper, a packaging consideration may take priority.

-

FieroWanaBe1

- Posts: 427

- Joined: Sun Mar 11, 2007 11:26 pm

Re: Spherical bearing upper strut mounts

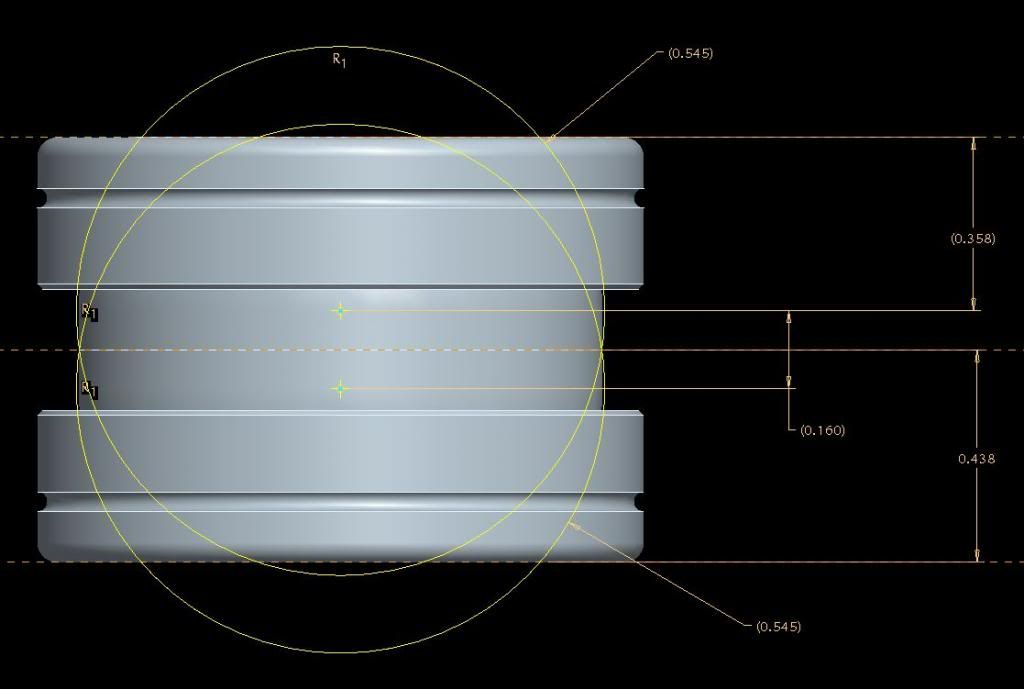

You're right about needing two spherical units, i see the flaw in my thinking. I feel as though using the body mount of the strut between the two sphericals makes the most sense in construction. Looking at the CAD of the mcmaster units, they cannot physically be mounted back to back the center of the arcs lay .160" apart.The Dark Side of Will wrote:Preload at full droop isn't relevant.

The upper spring seat will be retained on the strut shaft by the top nut. The spring will push against the lower face of the spring seat, while the upper face of the spring seat will mount the convex side of that spherical bearing. The concave side would be mounted to the body. There's nothing to prevent that bearing from coming apart once weight is off the wheels.

There will have to be a spacer between the two convex parts to make it an actual *spherical* bearing rather than an elliptical bearing with spherical faces (which wouldn't work...). That spacer could be a very stiff spring to double as a bump stop, too...

Also, you can't count on preload at full droop.

If you have 400# springs and 650# of sprung weight (750# corner weight less 100# of unsprung weight) and 2" of droop travel, there won't be preload at full droop. Also, the lower the static ride height, the greater the droop travel is...

Even if the wheel is at full droop, as long the the damper has reached the extent of its travel and the springs are still compressed any amount the spherical used for bearing the body load has some amount of preload from only the spring, while the top spherical is holding the total unsprung weight.

car.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15618

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Spherical bearing upper strut mounts

Yeah. The CAD doesn't say what the radius is, but they would need a spacer in between to make them an actual spherical bearing. This spacer *could* be a stiff spring (a high performance valve spring can have a rate greater than 500 ppi) that would double as a bump stop.FieroWanaBe1 wrote: Looking at the CAD of the mcmaster units, they cannot physically be mounted back to back the center of the arcs lay .160" apart.

Can't count on this... See my explanation above. 650# of sprung weight will compress a 400# spring 1.625". If the suspension has more droop travel than this, then there will be no preload at full droop. The stock suspension has more droop travel than this and stock length struts when lowered have even more than that.FieroWanaBe1 wrote:as long the the damper has reached the extent of its travel and the springs are still compressed any amount

-

FieroWanaBe1

- Posts: 427

- Joined: Sun Mar 11, 2007 11:26 pm

Re: Spherical bearing upper strut mounts

If the .stp export is to be trusted at all (that i cant be sure of) , that still wont work.The Dark Side of Will wrote:Yeah. The CAD doesn't say what the radius is, but they would need a spacer in between to make them an actual spherical bearing. This spacer *could* be a stiff spring (a high performance valve spring can have a rate greater than 500 ppi) that would double as a bump stop.FieroWanaBe1 wrote: Looking at the CAD of the mcmaster units, they cannot physically be mounted back to back the center of the arcs lay .160" apart.

.

A picture is worth a thousand words:

The spheres of rotation already .160" too far apart, spacing them .160" make the difference .320" not 0"

The solid model is probalby not accurate enough to make this assumption. It would be easy enough to determine the centerpoint with one in hand. there is probably other sphericals better suited for such an application so highly loaded axialy.

http://www.skf.com/portal/skf/home/prod ... link=3_3_1

This design doesn't make radial load the load holding priority.

car.