Turbo 3800 fuel system

Moderators: The Dark Side of Will, Series8217

Turbo 3800 fuel system

I want to switch away from from my current intake setup (blowing through the empty M90 case) and use either a L36 (return fuel system) or a L26 (returnless)

Any input or opinions are welcome.

Any input or opinions are welcome.

- Shaun41178(2)

- Posts: 8375

- Joined: Fri Nov 19, 2004 7:12 pm

- Location: Ben Phelps is an alleged scammer

Re: Turbo 3800 fuel system

I say keep the return system. Not sure of your hp goals, but a single 255 should provide enough for about 500 hp and is a straight drop in. If your goal is more, you can get a 450lph pump, but not sure if its a direct bolt in. I think its slightly bigger and might not fit the hangar like stock.

-

ericjon262

- Posts: 2833

- Joined: Mon May 24, 2010 5:34 pm

- Location: Aiken, SC

Re: Turbo 3800 fuel system

I have to agree, keep the current setup, I'm not sure what your power goals are, but a return style system should be a more capable fuel delivery system than returnless. all the returnless setup offers is less line in the engine bay.

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

Re: Turbo 3800 fuel system

And less heating of the fuel in the tank.ericjon262 wrote: all the returnless setup offers is less line in the engine bay.

Re: Turbo 3800 fuel system

I have a 340LPH pump in the tank, and 80lb injectors.

My thought was that If I converted to returnless fuel system I would use a C5 Corvette fuel filter/regulator assembly which would get me up to a 60psi or so base pressure but I'm not sure that helps me out much. It would clean up the engine bay and eliminate a vacuum line to the regulator.

My thought was that If I converted to returnless fuel system I would use a C5 Corvette fuel filter/regulator assembly which would get me up to a 60psi or so base pressure but I'm not sure that helps me out much. It would clean up the engine bay and eliminate a vacuum line to the regulator.

- Shaun41178(2)

- Posts: 8375

- Joined: Fri Nov 19, 2004 7:12 pm

- Location: Ben Phelps is an alleged scammer

Re: Turbo 3800 fuel system

you dont need 60 psi base pressure running 80 lb injectors. that 340 and 80s will support over 700 crank hp which is probably out of range of your hx40 anyways. I think the hx40 is only a 57mm compressor wheel. The corvette filter is not a a returnless system anyway is it? There is a built in regulator, but there is still a return line back to the tank with it right? It will clean up the engine bay with one fuel line I suppose.

FieroPhrek working on that ls4 swap for 18 years and counting now. 18 years!!!!! LOL

530 whp is greater than 312

530 whp is greater than 312

-

ericjon262

- Posts: 2833

- Joined: Mon May 24, 2010 5:34 pm

- Location: Aiken, SC

Re: Turbo 3800 fuel system

fieroguru wrote:And less heating of the fuel in the tank.ericjon262 wrote: all the returnless setup offers is less line in the engine bay.

I'd be interested in seeing the hard data on how much hotter the fuel gets... I would bet it's a very small amount

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

Re: Turbo 3800 fuel system

The Vette filter is a sweet piece for conversions I've use it alot on LS swaps. the filter has a 62psi regulator built in and is designed to feed a retunless rail.

Re: Turbo 3800 fuel system

I have been doing a lot of reading on the internet about this, and it seems like most people making a lot of HP and have a factory returnless system are looking to convert to a return system.

Example #1 Returnless fuel system with 62PSI in the rail running 20PSI of boost = 42PSI @ the Injector in boost

Example #2 Return fuel system with factory fuel pressure regulator and 43.5PSI in the rail running 20PSI boost = 43.5PSI if the FPR can keep up.

It seems like #1 would be difficult to tune because Injector flow would depend on boost pressure & flow would drop as boost goes up

Example #1 Returnless fuel system with 62PSI in the rail running 20PSI of boost = 42PSI @ the Injector in boost

Example #2 Return fuel system with factory fuel pressure regulator and 43.5PSI in the rail running 20PSI boost = 43.5PSI if the FPR can keep up.

It seems like #1 would be difficult to tune because Injector flow would depend on boost pressure & flow would drop as boost goes up

Re: Turbo 3800 fuel system

I don't have any hard data, but think about it, pumping fuel through 3' to 4' length of hard line in an environment that is pushing 150+ degrees. It will pick up heat and return it to the fuel tank.ericjon262 wrote:I'd be interested in seeing the hard data on how much hotter the fuel gets... I would bet it's a very small amountfieroguru wrote:And less heating of the fuel in the tank.ericjon262 wrote: all the returnless setup offers is less line in the engine bay.

http://www.airtexproducts.com/news-supp ... h-low-risk

The newer ECMs have an injector flow rate table based on manifold vacuum (and positive pressure), so it just adjusts the injector pulse width based on the current injector flow rate and the needed fuel flow. When they run return-less, all the values are different because the pressure drop across the injector is constantly changing with MAP. When they run with a return style system, all the values are the same as the pressure drop across the injector is more uniform because MAP is referenced on both sides of the regulator.1fast2m6 wrote: It seems like #1 would be difficult to tune because Injector flow would depend on boost pressure & flow would drop as boost goes up

The hard part is knowing what the injector flow rate is at all the MAP values, but many of the injector vendors supply this information, or you can stick with GM injectors that you can pull the injector flow data from other tunes.

Once you get above 7-10 psi, you are probably better going to a return system (or atleast a vacuum reverenced regulator) as you might run out of injector pulse width otherwise.

Not sure what the 3800 ecms have, but the LS(x) ecms have the tables to run either method.

Re: Turbo 3800 fuel system

I am semi familiar with the "Flow Vs. Kpa" , But as far as I know, at least in my PCM. The PCM can't account for positive pressure in Flow vs KPA just 0-100KPA vacuum

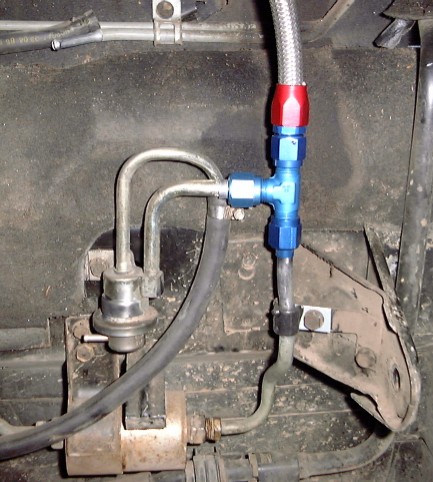

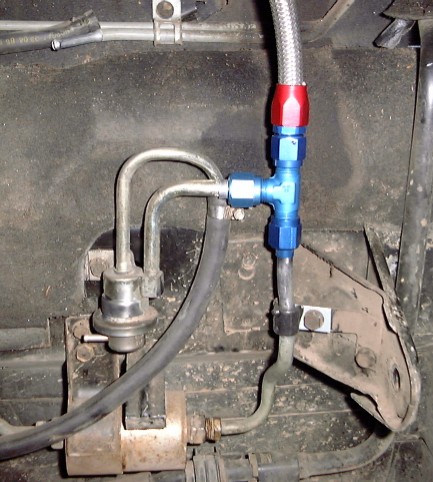

After many more hours of mindless surfing I think I'll do this

I think I'll do this

A single line to the L26 Rail, a T fitting and a Modified L67 regulator.

It's the same idea as the vette filter combo, but @ 43psi

After many more hours of mindless surfing

A single line to the L26 Rail, a T fitting and a Modified L67 regulator.

It's the same idea as the vette filter combo, but @ 43psi

- Shaun41178(2)

- Posts: 8375

- Joined: Fri Nov 19, 2004 7:12 pm

- Location: Ben Phelps is an alleged scammer

Re: Turbo 3800 fuel system

going returnless for big power cars is almost what everyone does. It is dependable and many tuners find it easier to tune with a constant fuel rail pressure, vs modifying the voltage tables of the pumps to raise or lower pressure, thus injector flow.1fast2m6 wrote:I have been doing a lot of reading on the internet about this, and it seems like most people making a lot of HP and have a factory returnless system are looking to convert to a return system.

Example #1 Returnless fuel system with 62PSI in the rail running 20PSI of boost = 42PSI @ the Injector in boost

Example #2 Return fuel system with factory fuel pressure regulator and 43.5PSI in the rail running 20PSI boost = 43.5PSI if the FPR can keep up.

It seems like #1 would be difficult to tune because Injector flow would depend on boost pressure & flow would drop as boost goes up

If you use a stock fpr, it is boost referenced at 1:1 so if you run a base pressure of 43 psi, and 20 psi of boost, you will have approx 63 psi at the rail, not 43 like you quoted. If you leave the vacuum line off the fpr, then fuel pressure will never change. I don't recommend that. With 80 lb injector you might be able to get away with it though. It would probably be easier to get 60 lb injectors running for idle and low throttle conditions, and boost referenced from the fpr will bump injector flow to around 72 lb/hr on 20 psi of boost.

-

ericjon262

- Posts: 2833

- Joined: Mon May 24, 2010 5:34 pm

- Location: Aiken, SC

Re: Turbo 3800 fuel system

you're both correct, you're just thinking about it in different ways, 1fast2m6 is comparing fuel pressure to manifold pressure, you're comparing it to ambient pressure.Shaun41178(2) wrote:going returnless for big power cars is almost what everyone does. It is dependable and many tuners find it easier to tune with a constant fuel rail pressure, vs modifying the voltage tables of the pumps to raise or lower pressure, thus injector flow.1fast2m6 wrote:I have been doing a lot of reading on the internet about this, and it seems like most people making a lot of HP and have a factory returnless system are looking to convert to a return system.

Example #1 Returnless fuel system with 62PSI in the rail running 20PSI of boost = 42PSI @ the Injector in boost

Example #2 Return fuel system with factory fuel pressure regulator and 43.5PSI in the rail running 20PSI boost = 43.5PSI if the FPR can keep up.

It seems like #1 would be difficult to tune because Injector flow would depend on boost pressure & flow would drop as boost goes up

If you use a stock fpr, it is boost referenced at 1:1 so if you run a base pressure of 43 psi, and 20 psi of boost, you will have approx 63 psi at the rail, not 43 like you quoted. If you leave the vacuum line off the fpr, then fuel pressure will never change. I don't recommend that. With 80 lb injector you might be able to get away with it though. It would probably be easier to get 60 lb injectors running for idle and low throttle conditions, and boost referenced from the fpr will bump injector flow to around 72 lb/hr on 20 psi of boost.

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

-

The Dark Side of Will

- Peer Mediator

- Posts: 15630

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Turbo 3800 fuel system

That's the thing to do. That uses a manifold pressure-referenced regulator for constant injector flow rates, but puts the fuel rail on a shunt and avoids the problem of the returning fuel heating the tank.1fast2m6 wrote:I am semi familiar with the "Flow Vs. Kpa" , But as far as I know, at least in my PCM. The PCM can't account for positive pressure in Flow vs KPA just 0-100KPA vacuum

After many more hours of mindless surfingI think I'll do this

A single line to the L26 Rail, a T fitting and a Modified L67 regulator.

It's the same idea as the vette filter combo, but @ 43psi

However, I suggest you look into aftermarket FPR's instead of the hacked up 3800 unit.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15630

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Turbo 3800 fuel system

Drive your Fiero 200 miles, then remove the shift console and touch the top of the center tunnel.ericjon262 wrote:I'd be interested in seeing the hard data on how much hotter the fuel gets... I would bet it's a very small amountfieroguru wrote:And less heating of the fuel in the tank.ericjon262 wrote: all the returnless setup offers is less line in the engine bay.

It's not the environment so much as it is the pipe that's bolted to the 195 degree engine. Putting the engine-mounted fuel rail on a shunt as shown above via remote mount manifold-referenced regulator gets that aspect out of the system.fieroguru wrote: I don't have any hard data, but think about it, pumping fuel through 3' to 4' length of hard line in an environment that is pushing 150+ degrees. It will pick up heat and return it to the fuel tank.

The only reason OEM's use returnless fuel systems is to save the cost of the return pipe (and the vacuum line to the regulator). They can get adequate performance by messing with things in software and remove a (really two) components from the car... win/win for them.

- Series8217

- 1988 Fiero Track Car

- Posts: 5981

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: Turbo 3800 fuel system

That's probably from all the hot radiator air blowing past it. When I had my full length belly pan installed the center tunnel got HOT because the air didn't blow out to the sides at all; it just flowed around the fuel tank.The Dark Side of Will wrote: Drive your Fiero 200 miles, then remove the shift console and touch the top of the center tunnel.

Re: Turbo 3800 fuel system

As far as I know the returnless system is based on Evaporative emissions primarily...

I too have never seen data to back up how much heat (from fuel) is placed back into the tank, but I am willing to bet it is not far off from the fuel just sitting in the rail hit soaking either...

in any regards, to control fuel consistently I will stick with a return system...so long as the pump can generate enough psi for your hp goals...more parts but less headaches when you want to start playing with power...

I too have never seen data to back up how much heat (from fuel) is placed back into the tank, but I am willing to bet it is not far off from the fuel just sitting in the rail hit soaking either...

in any regards, to control fuel consistently I will stick with a return system...so long as the pump can generate enough psi for your hp goals...more parts but less headaches when you want to start playing with power...