originally, I planned on making the bolt ring stay inside the tank and not weld on the tank, I found that making a weld on ring was easier, and probably a better bet. I made the weld on ring, as well as some nickel acetate, after the ring was finished, I dunked it in the acetate, applied a small current, and nickel plated the bare steel to hopefully keep it from rusting.

I opened the hole up in the top of the tank, and welded it in. The hole was about 135mm

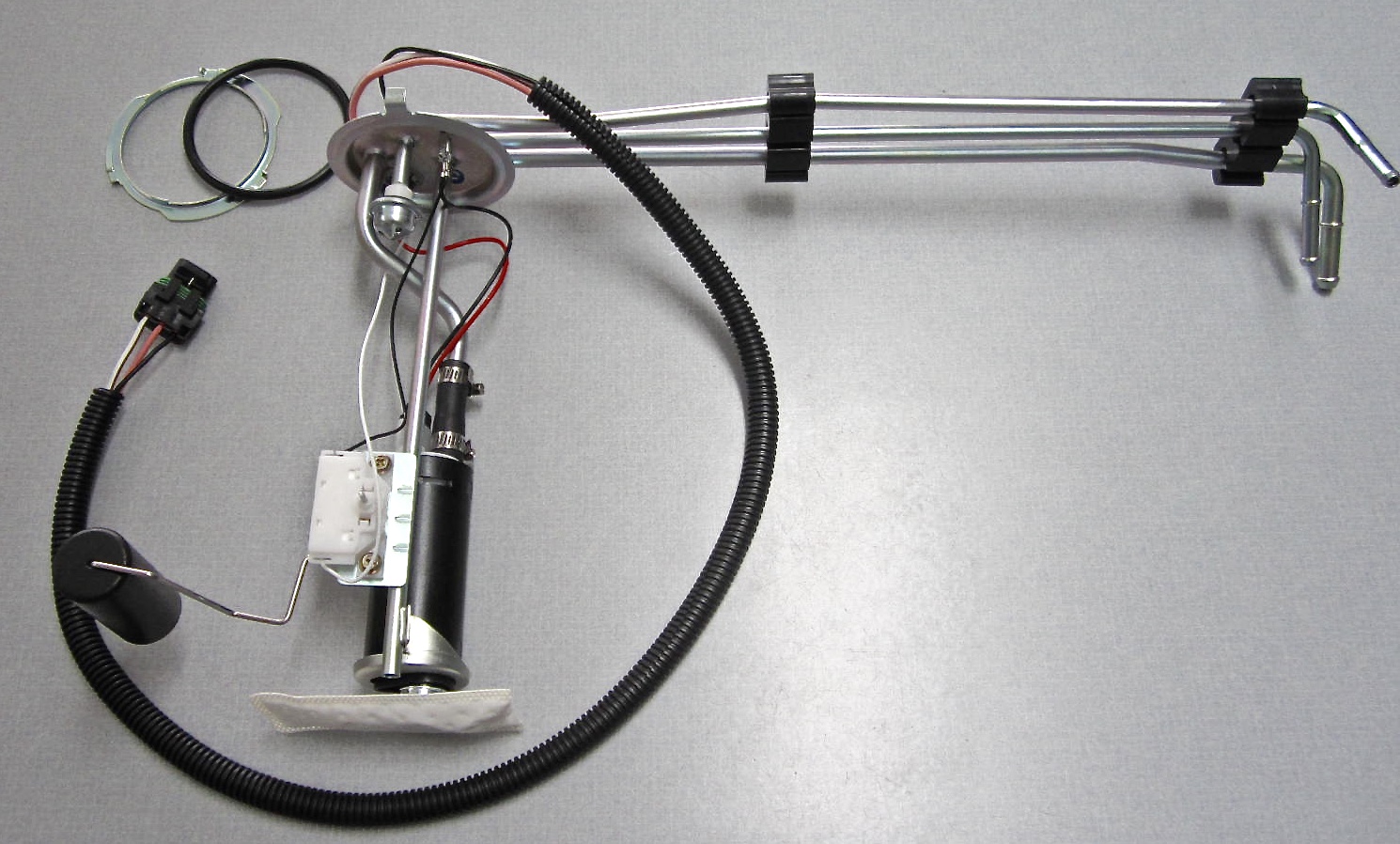

The new top hat fully machined

I soldered in the pump discharge tube, and a ground stud that goes all the way through.

I cut the rest of the parts on the plasma cutter.

After that, I installed the return, and the all thread that would actually hold the pumps in place, and test fit everything.

The into the nickel with the top hat, I wasnt' worried about the tubes or all thread, because the tubes are stainless, and the all thread was zinc plated, so both of those should fair ok from a corrosion standpoint without the nickel plating.

Then I bent the tubes to fit the car.

I soldered the tubes in, wired everything up, fuel pump 1 on terminal "A" the level sender on "B", and fuel pump 2 on "C", and installed it on the tank. what's left? I have compression fittings for the tubes to adapt them to the rest of the fuel system, I also need to made some blocks to go between the tank and the tubes to adequately support them and not stress the solder joints. I'm planning on moving the flexfuel sensor to be closer to the tank/fuel filter, and not on the fuel rail, as well as installing a set of stainless LX9 fuel rails.

Parts used:

https://www.racetronix.biz/p/double-pum ... red/dpc-g6

https://www.racetronix.biz/p/universal- ... y/bcws-001

https://www.highflowfuel.com/quantum-pe ... ces-11569/

https://www.racetronix.biz/p/connector- ... ga/rcs-001

and the appropriate fittings.

Some notes about the nickel plating, I learned about this through a few youtube videos, Turbo_V6 zinc plated a trigger wheel, while looking for a few other videos on zinc, I found nickel was also doable.

Turbo_V6's zinc plating video:

https://youtu.be/O486S9CGhgM

and a helpful nickle plating video:

https://youtu.be/1Uy7QkLI8yU

My results were hit and miss, some parts turned out great, others not so much, I think my acetate may be contaminated with zinc, as some of my parts came out with a very dark finish, and the zinc plated all thread that was exposed to the acetate also turned black. if there's a next time for this, I'll do a few things slightly different:

1. insulate parts that don't need plating, this should help focus the plating on that parts that need it

2. attempt to arrange the anode(s) in such a manner that they present themselves to the entire part, or the largest surface area of the part.

3. increase the number of anodes, so that they surround the part and and more of the part is equidistant to a anode,

4. install a pump to circulate the acetate, and maybe a small filter to prevent solids that come off the anodes from getting to the part to be plated.

5. get a parts tumbler to polish small parts prior to plating, I suspect some of my parts may have had surface contaminants which caused discoloration.

6. acid dip parts prior to plating, which should further help with stripping contaminants.

I'm confident my parts are now corrosion resistant, as can be seen in one of the pictures of the top hat after soldering in the ground stud and the pump discharge pipe, the flux used to solder the parts in cause the steel to rust very quickly, while soldering in the tubes on the outside of the sender, the top hat did not rust.

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."