The Mule rides again (sort of) - pics.

Moderators: The Dark Side of Will, Series8217

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Does that have the small diameter mounting barrel like the Fiero brake light switch?

The switch/vacuum dump that I replaced with the corresponding unit from the other side had a large diameter mounting barrel.

The switch/vacuum dump that I replaced with the corresponding unit from the other side had a large diameter mounting barrel.

-

ericjon262

- Posts: 2843

- Joined: Mon May 24, 2010 5:34 pm

- Location: Aiken, SC

Re: The Mule rides again (sort of) - pics.

small diameter, but it still fits just fine, and best of all, it was free (off an old parts car). I could make an adapter bushing if it was a big deal to me, but it's not, so I wont.The Dark Side of Will wrote:Does that have the small diameter mounting barrel like the Fiero brake light switch?

The switch/vacuum dump that I replaced with the corresponding unit from the other side had a large diameter mounting barrel.

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Pics:

MAF housing, Throttle Body, TB Adapter, manifold flange. TB and Adapter faces shown mate

MAF housing, Throttle Body, TB Adapter, manifold flange. TB and MAF housing faces shown mate; Adapter and manifold flange faces shown mate.

Old assembly vs. new parts. My high tech EGR blockoff plate is visible on the old TB adapter. It had to be modified slightly to work with the new hottness.

Throttle cable bracket... will take a pic of how I modded it sometime.

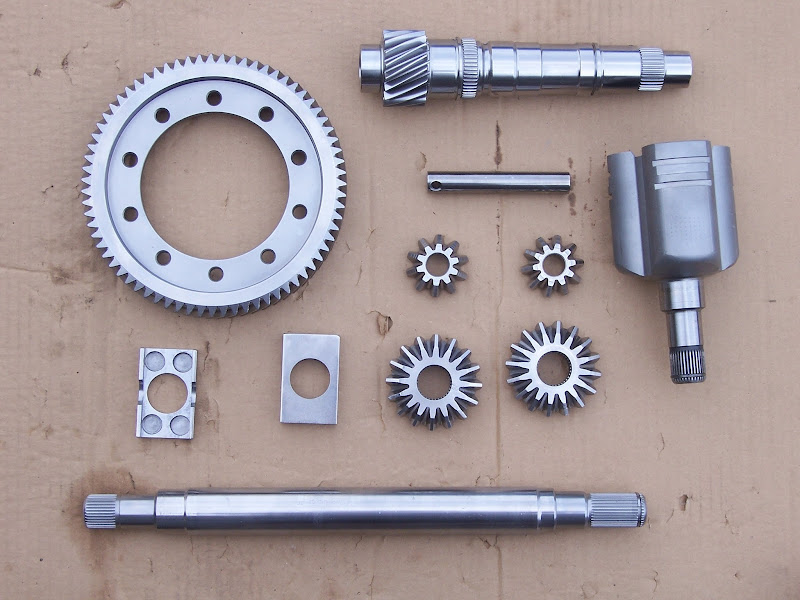

Full set of components that went through Liberty's Cryo+mikronite-like process: Getrag 3.94 R&P; Type II IMS; couple of extra CV joint cups (I think these were cryo only); side gears, spider gears and cross pin from the later style larger Getrag diff; spring plates from an EP LSD for same.

3.94 output shaft... hardness testing marks are *just* barely visible

3.94 output shaft gear teeth and 1-2 synchro splines. Blingin'

One of the spider gears, also with hardness testing marks visible

Transmission end of Type II IMS

3.94 ring gear. It also has hardness testing marks on the ends of some of the teeth, but those aren't visible in this angle/lighting.

MAF housing, Throttle Body, TB Adapter, manifold flange. TB and Adapter faces shown mate

MAF housing, Throttle Body, TB Adapter, manifold flange. TB and MAF housing faces shown mate; Adapter and manifold flange faces shown mate.

Old assembly vs. new parts. My high tech EGR blockoff plate is visible on the old TB adapter. It had to be modified slightly to work with the new hottness.

Throttle cable bracket... will take a pic of how I modded it sometime.

Full set of components that went through Liberty's Cryo+mikronite-like process: Getrag 3.94 R&P; Type II IMS; couple of extra CV joint cups (I think these were cryo only); side gears, spider gears and cross pin from the later style larger Getrag diff; spring plates from an EP LSD for same.

3.94 output shaft... hardness testing marks are *just* barely visible

3.94 output shaft gear teeth and 1-2 synchro splines. Blingin'

One of the spider gears, also with hardness testing marks visible

Transmission end of Type II IMS

3.94 ring gear. It also has hardness testing marks on the ends of some of the teeth, but those aren't visible in this angle/lighting.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Made some progress on the intake tube: 3.5" aluminum tubing. The bends are from tight radius 3.5" donut halves that I had to order from F@#$ing Australia. The straight sections were rolled by a local sheet metal shop.

-

ericjon262

- Posts: 2843

- Joined: Mon May 24, 2010 5:34 pm

- Location: Aiken, SC

Re: The Mule rides again (sort of) - pics.

looks awesome!

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Does your clutch pedal switch bracket take the small diameter mounting barrel? Mine required the large diameter mounting barrel.ericjon262 wrote:small diameter, but it still fits just fine, and best of all, it was free (off an old parts car). I could make an adapter bushing if it was a big deal to me, but it's not, so I wont.The Dark Side of Will wrote:Does that have the small diameter mounting barrel like the Fiero brake light switch?

The switch/vacuum dump that I replaced with the corresponding unit from the other side had a large diameter mounting barrel.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Thanks! It's getting there...ericjon262 wrote:looks awesome!

I spray washed the underside of the engine bay again yesterday... I was able to verify that the front cam cover seal is leaking. At least the oil filter adapter is no longer leaking. I stopped by the dealership today and ordered a new front cam cover seal as well as PCV tubes. The cam cover and spark plug o-rings from the dealership were almost as much as the whole kit for both sides from CarQuest.

The last time I fixed this leak, I wasn't able to tilt the engine down far enough to have good access to reinstall the front cam cover due to a stud on the trunk firewall that originally secured one side of the alternator blower tube. I @$$ume that the seal shifted during installation. Because I couldn't see it for shit once the cover was in place, I wasn't able to get it right. Swinging the engine down a bit further should allow me to do better. I'll cut the stud off to allow that. I may also elongate the hole in the cam cover that the water pump drive goes through.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Series8217 wrote:I have a ScanTool 426101 OBDLink MX Bluetooth/OBD-II Scan Tool Interface and a Nexus 7 (Android Tablet) with the Torque Pro app. I'll try to generate some logs this week from the Apocalypse Wagon and upload them to my website so you can see how it does.

I bought the OBDLink MX linked above. The manufacturers have their own app that gives some OBDII PID's. I don't think I saw KR on the list, but I think it had everything else on the above list. I was using my G/F's phone, so I haven't downloaded Torque Pro yet.Sinister Fiero wrote:I'm glad to hear it starts, runs, and idles. Concerning the tune, the one unknown for me was exactly what MAF sensor the Shelby used. I didn't have that information and I'm betting the MAF calibration is off in your tune for the MAF sensor you are using on your engine.

The open to closed loop transition hiccup is something I've experienced on a few 1998 3800 tunes and I'm not sure what is causing it. Using a 99 3800 OS on the same PCM and engine, the problem went away. Unfortunately, we only have one OS for the Shelby tune so some digging might be required to 1) first determine what is going on causing the hiccup and then 2) what needs to be done to correct the problem - if it can even be corrected.

I would really like to see some data from this 1st tune I made you based on the Shelby code. The absolute cheapest way to go would be the Android Torque Pro app and ELM OBD interface that I talked about in the thread I started on Old Europe. HOWEVER, I'm not sure this app is going to give use enhanced data PIDs for this Shelby OS. I don't have anything with the Shelby tune on it here at my shop to try it out on. At the very least, you are going to need the following data PIDs available MINIMUM to log no matter what you use to get data:

-MAF flow (gm/sec or Hz)

-MAP (kpa)

-ECT (coolant temp)

-RPM

-KR (knock retard)

-B1S1 & B2S1 O2 sensor voltage

-B1 Short & Long Term Fuel Trims

-B2 Short & Long Term Fuel Trims

Anything else is a bonus.

HP Tuners VCM Scanner should do the job. Not sure about anything else (including Torque Pro).

-ryan

Have a tuning appointment scheduled for tomorrow morning. We'll see how things go.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

Did get it to the dyno today.

Final numbers for the day: 312 RWHP / 305 RWTQ

It picked up 12 HP and 17 ftlbs compared to the previous dyno.

Was having beaucoups of problems with knock retard due to having the OBDI knock sensor hooked up to the OBDII computer. I was able to pick up the correct knock sensor today, but it uses a different electrical connector AND a different mechanical interface. CarQuest will have the pigtail for me tomorrow, but I'll have to custom make an adapter bushing to screw the 10x1.5mm sensor into the pipe thread boss (not sure if it's 1/4" pipe or 1/8" pipe) on the side of the block.

More detailed write-up later.

Final numbers for the day: 312 RWHP / 305 RWTQ

It picked up 12 HP and 17 ftlbs compared to the previous dyno.

Was having beaucoups of problems with knock retard due to having the OBDI knock sensor hooked up to the OBDII computer. I was able to pick up the correct knock sensor today, but it uses a different electrical connector AND a different mechanical interface. CarQuest will have the pigtail for me tomorrow, but I'll have to custom make an adapter bushing to screw the 10x1.5mm sensor into the pipe thread boss (not sure if it's 1/4" pipe or 1/8" pipe) on the side of the block.

More detailed write-up later.

- Shaun41178(2)

- Posts: 8375

- Joined: Fri Nov 19, 2004 7:12 pm

- Location: Ben Phelps is an alleged scammer

Re: The Mule rides again (sort of) - pics.

find a way to get into the code, so that it disables the knocks sensor. You are running 93 and are naturally aspirated. Not only that but you have it tuned now. I see no reason why you need it anymore.

How much timing were you running?

Also good numbers. How about a graph

How much timing were you running?

Also good numbers. How about a graph

-

ericjon262

- Posts: 2843

- Joined: Mon May 24, 2010 5:34 pm

- Location: Aiken, SC

Re: The Mule rides again (sort of) - pics.

it had the larger diameter hole. I'll make it the right size one day, or make a bushing for it. I tightened the "nut" up, and it doesn't move, so it'll do until I drop the pedals again.The Dark Side of Will wrote:Does your clutch pedal switch bracket take the small diameter mounting barrel? Mine required the large diameter mounting barrel.ericjon262 wrote:small diameter, but it still fits just fine, and best of all, it was free (off an old parts car). I could make an adapter bushing if it was a big deal to me, but it's not, so I wont.The Dark Side of Will wrote:Does that have the small diameter mounting barrel like the Fiero brake light switch?

The switch/vacuum dump that I replaced with the corresponding unit from the other side had a large diameter mounting barrel.

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

The way that makes sense is just to install the correct knock sensor. The engine is naturally aspirated, but also has 11.5 static compression and fairly mild intake cams that result in high dynamic compression.Shaun41178(2) wrote:find a way to get into the code, so that it disables the knocks sensor. You are running 93 and are naturally aspirated. Not only that but you have it tuned now. I see no reason why you need it anymore.

How much timing were you running?

Also good numbers. How about a graph

The tuner is supposed to send me the run file so I can generate my own graph and overlay with my previous graphs.

Also, since the layoff I don't have ready access to a scanner.

Weather couldn't have been better. It was in the '70's with lowish humidity.

I arrived just a few minutes after 9; I was a little late because traffic on I-66 was even worse than usual... literally 5-10 mph for 10+ miles into the beltway. Fortunately, I only had to be on for 5 of that. The tuner didn't get to the shop for about another 45 minutes. It was 10:30 when we getting the car on the dyno and strapped down.

Did pulls for 3 hours and was off the dyno by 1:45ish.

The first pull took a looooong time and filled the shop with black smoke. I didn't even see the graph from that one, but it was in the low 100's due to knock retard and ridiculously rich AFR. The tuner worked on it for a long time, and while talking to him I remembered that GM changed the knock sensor impedance characteristics for OBDII, but I still had the OBDI sensor. D-oh. While driving it, I had been feeling timing coming in and out as I dipped into a little more throttle than it liked on the street. He turned the knock sensitivity down as far as it would go and was able to work up to the 312 number I posted above. After the session he noted that the ECM had set a knock sensor low voltage code.

All the guys working in the shop swung by at one point or another to look at the engine bay. Most of them shook their heads. One guy asked how the heck I was able to get that engine into the car. Everyone thought it sounded fantastic.

Final damage, including a one-time $100 for an extra HPTuners license for my application was $450... so ~3 hours of dyno time was $350. Not bad.

Shop: http://www.mooreautomotive.com/

When I have the knock sensor problem corrected, my intake pipe finished and that F@#$ing front valve cover leak fixed, I'll go back for a touch up. I didn't think about the wideband port in my X-pipe until the car was strapped down to the dyno, so I'd like to have the wideband in that port instead of the tailpipe next time also.

-

Sinister Fiero

- Posts: 665

- Joined: Tue Jun 07, 2005 12:10 pm

- Location: Waterloo, Indiana

- Contact:

Re: The Mule rides again (sort of) - pics.

I take it the MAF calibration I put in was way off?

How much VE tuning work did he have to do?

How much VE tuning work did he have to do?

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

He's supposed to email me the DynoJet files... I'll try to get the .BIN file for you also.

-

Sinister Fiero

- Posts: 665

- Joined: Tue Jun 07, 2005 12:10 pm

- Location: Waterloo, Indiana

- Contact:

Re: The Mule rides again (sort of) - pics.

If he can supply us with the current .bin file he last programmed into your PCM, I can run a comparison vs. stock Shelby tune (and also one comparison with the tune I made for you) and post the differences so we know what had to be changed. Of course your engine is far from stock so this information probably wouldn't help the general public. But it would satisfy our curiosity about your engine at least.The Dark Side of Will wrote:He's supposed to email me the DynoJet files... I'll try to get the .BIN file for you also.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

I would expect that the tune from my engine would be somewhat applicable to a stock engine. I'm still running stock throttle, manifold, heads, cams and displacement.

My ring package pulls way more air at high RPM than the stock setup, and I can see that would throw off a speed-density tune, but shouldn't affect a MAF tune much.

The other big difference between my engine and stock is compression, quench and the piston crown coating. Again, I'm not sure how that affects a MAF tune.

I will be changing from my current crappy intake tube to the one shown above sometime soon. That will probably affect the MAF calibration a bit.

My ring package pulls way more air at high RPM than the stock setup, and I can see that would throw off a speed-density tune, but shouldn't affect a MAF tune much.

The other big difference between my engine and stock is compression, quench and the piston crown coating. Again, I'm not sure how that affects a MAF tune.

I will be changing from my current crappy intake tube to the one shown above sometime soon. That will probably affect the MAF calibration a bit.

-

Sinister Fiero

- Posts: 665

- Joined: Tue Jun 07, 2005 12:10 pm

- Location: Waterloo, Indiana

- Contact:

Re: The Mule rides again (sort of) - pics.

The Shelby OS is much like the LS1 OS. The LS1 OS relies heavily on the VE tables with "relatively" little input from the MAF sensor until a certain RPM threshold is surpassed (usually 4000 rpm). The MAF signal still does influence fueling, but it does not have primary control over it. This is why a VE tune is critical on LS and other V8 tunes for PCMs of this era. In order to do a VE tune, the MAF must be set to "fail" in the programming and other things need to be done to properly lock the PCM into speed density mode. Once VE tuning is completed, the MAF can be re-enabled and then you can work on the MAF calibration. But my experience with tuning LS PCMs has proven it to be a real PITA to try to do both MAF and VE tuning simultaneously.

In contrast, 3800 and most other FWD V6 OBD2 OS's primarily use the MAF sensor for making ALL fuel and spark calculations and only fall back to using VE table values if there is a MAF fault. As a result, it is much easier to tune 3800 and other FWD V6 OS's because you usually don't have to mess with the VE tables at all.

In contrast, 3800 and most other FWD V6 OBD2 OS's primarily use the MAF sensor for making ALL fuel and spark calculations and only fall back to using VE table values if there is a MAF fault. As a result, it is much easier to tune 3800 and other FWD V6 OS's because you usually don't have to mess with the VE tables at all.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

The guy had a good bit of experience tuning LS1's, and was recommended to me by the machine shop who did my block work. They really know their S@#$, so I figured the recommendation was good. I told him it would be like tuning a full-bolt-on LS1 Camaro that still had the factory tune and he seemed pretty comfortable with that.

The way you describe the 3800 PCM's working is how I thought all MAF-based systems worked, but I see that's not correct. It's interesting that it's such a complicated interplay. I assume that's because of potential reversion at lower speeds and loads?

A few years ago, I read a comparison test of some mostly German super-sedans (it may have included a first-gen CTS-V... don't recall). The Mercedes in the mix became all but disabled with an air flow sensor fault. I thought it was hilarious that a car with Mercedes engineering and a 6 figure price tag would be completely sidelined by a fault that would cause a $30K (at the time) Camaro to do nothing more than light it's MIL.

The way you describe the 3800 PCM's working is how I thought all MAF-based systems worked, but I see that's not correct. It's interesting that it's such a complicated interplay. I assume that's because of potential reversion at lower speeds and loads?

A few years ago, I read a comparison test of some mostly German super-sedans (it may have included a first-gen CTS-V... don't recall). The Mercedes in the mix became all but disabled with an air flow sensor fault. I thought it was hilarious that a car with Mercedes engineering and a 6 figure price tag would be completely sidelined by a fault that would cause a $30K (at the time) Camaro to do nothing more than light it's MIL.

-

Sinister Fiero

- Posts: 665

- Joined: Tue Jun 07, 2005 12:10 pm

- Location: Waterloo, Indiana

- Contact:

Re: The Mule rides again (sort of) - pics.

Potential reversion might have been why they did it. Another possibility is the location they elected to put the MAF sensor at in the induction system. On most FWD V6 stuff, it's either on the throttle body or very close to it. On the LS and Truck V8 stuff, it can be feet away from the throttle body. The further the MAF sensor is from the throttle body, the more delay there is in MAF response time for airflow changes.The Dark Side of Will wrote:

The way you describe the 3800 PCM's working is how I thought all MAF-based systems worked, but I see that's not correct. It's interesting that it's such a complicated interplay. I assume that's because of potential reversion at lower speeds and loads?

Here's the description from TunerCat OBD2 on the 4000 rpm threshold for switching over to primary use of MAF sensor values:

"This constant sets the engine RPM above which the MAF sensor readings are used instead of the predicted mass air value based on the volumetric efficiency table."

I'm sure it has something to do with reversion, but there's got to be more to it than that. Sometimes I wonder if the GM Engineering Dept. merely extended development of OBD2 code based on existing OBD1 code. Remember that OBD1 3800 fuel and spark stuff was based solely on MAF sensor input since the mid 80's. V8 port injected stuff was speed density from 1990 until 1994 when the flash-based LT1 PCM came along; then they started that bastard way of using MAF & VE to both calculate fuel in the 94-95 OBD1 LT1 systems. When they switched to OBD2 in 1996, perhaps they just continued using the same method of operation from the OBD1 LT1 PCMs. If you look at 1996-97 LT1 PCM tables, they don't look much different at all from 94-95 LT1 stuff. Perhaps LS OS's were still based on LT1 OS's and newer OS's were developed on the same line of operation.

What would be nice would be for custom tuning support to be added for OBD1 and early OBD2 Northstar stuff. I wonder if the Northstar stuff operates much like the 3800 OS's.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15637

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: The Mule rides again (sort of) - pics.

I'm using a '98 Northstar MAF. As you can see in the photos I posted previously, it's bolted right to the throttle, so there shouldn't be any lag associated with using that MAF.

I'm sure GM did the minimum development work necessary to make what they already had compliant with OBDII requirements.

The OBDI Northstar PCM is a dual processor, dual EPROM job. I've emailed TunerCat several times about developing a definition file for it, but I was apparently the only one. I don't think I've worried any about that since 2005.

The '96-'99 Northstar PCM is a Siemens deal that's, AIUI, way out of family with the rest of GM's products... I have no idea why. Other than the throttle body, the engine's hard parts are all the same.

I don't know much about the '00-'04(?) PCM, other than that the Northstar had a semi-unique trigger wheel. I've been told those engines used a wheel that was the inverse of the LS1 24x wheel... so it *may* be possible to adapt an LS1 controller to those engines, assuming that the right crank position sensor offset can be set in the LS1 controller. IIRC, the LS1's have the crank sensor on the right side of the engine at the crank centerline, while the Northstars have two on the left side of the engine, just above and below crank centerline. These engines share relatively few parts with the '93-'99 engines.

In '05 the Northstar joined the rest of the GM world with a 58x reluctor wheel. The crank sensor is in the V underneath the intake manifold next to the starter on those engines.

I'm sure GM did the minimum development work necessary to make what they already had compliant with OBDII requirements.

The OBDI Northstar PCM is a dual processor, dual EPROM job. I've emailed TunerCat several times about developing a definition file for it, but I was apparently the only one. I don't think I've worried any about that since 2005.

The '96-'99 Northstar PCM is a Siemens deal that's, AIUI, way out of family with the rest of GM's products... I have no idea why. Other than the throttle body, the engine's hard parts are all the same.

I don't know much about the '00-'04(?) PCM, other than that the Northstar had a semi-unique trigger wheel. I've been told those engines used a wheel that was the inverse of the LS1 24x wheel... so it *may* be possible to adapt an LS1 controller to those engines, assuming that the right crank position sensor offset can be set in the LS1 controller. IIRC, the LS1's have the crank sensor on the right side of the engine at the crank centerline, while the Northstars have two on the left side of the engine, just above and below crank centerline. These engines share relatively few parts with the '93-'99 engines.

In '05 the Northstar joined the rest of the GM world with a 58x reluctor wheel. The crank sensor is in the V underneath the intake manifold next to the starter on those engines.