Page 3 of 4

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Fri Jan 04, 2013 7:12 pm

by Series8217

Well, the Fidanza aluminum flywheel is loose now. It was fine for a couple years but after an autocross event it has started to get worse in a hurry. I'm hardly surprised, considering the concerns I had about the design in the first place. I think the aluminum is just too soft for the small area that the bolt heads are clamping on. I did some googling and loose aluminum flywheels seems to be a common problem. The Toyota folks solved it by adding a spacer plate like the flexplates use -- it spreads out the clamping force more evenly and prevents the aluminum from flowing under the bolt head.

I'm not sure what I'm going to do this time around. Once I have the drivetrain pulled out and I can assess the damage to my crankshaft and the flywheel I'll have enough information to devise a solution.

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Fri Jan 04, 2013 7:19 pm

by Aaron

What are the symptoms of the flywheel being loose? How could you tell? I've got the same flywheel, although I've put far less miles on it than you I assume. Thanks!

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Fri Jan 04, 2013 7:28 pm

by Series8217

Well, the last time I pulled my drivetrain, the flywheel had been loose and I didn't know until I pulled it out. It didn't really make any noise, but it banged forward and back since the bolts are smaller than the holes. I was able to shift it around by yaking on it after I pulled the engine off the trans.

This time, it sounds kinda like the Getrag rattle but MUCH louder. Initially, the noise went away with the clutch pedal pressed down. Then it started to make the noise a bit even with the pedal pushed down. It got worse very quickly. Also, on decel it makes a weird noise, kind of a rattling. At least I think that's from the flywheel.

When I had a stock steel flywheel come loose before, it sounded a bit like the Getrag rattle, but lower pitched and sounded a little more like "banging" than rattling.

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Sun Jan 06, 2013 3:16 pm

by Series8217

Got everything apart. There is some very abnormal clutch wear on the flywheel. The pressure plate wear looks ok though there is one strip where the clutch did not engage the pressure plate. Also this clutch (Clutchnet 6-puck) was VERY aggressive to both the flywheel and pressure plate surfaces.

There was some aluminum stuck to the crank, but a chisel removed that easily without marring the crankshaft metal.

The loctite was still holding quite strongly -- it took like 30 ft lbs just to rotate the bolts. However, they were just loose enough to allow the flywheel to have some slop. There are rings of compressed aluminum under where the heads of the bolts meet the flywheel. I suspect the aluminum cold flows under the bolt heads. A steel spreader plate would likely fix that problem.

I measured the Fidanza flywheel and it's 1mm thicker than the stock steel flywheel where the bolts go through, leaving about 11 mm of thread engagement instead of 12 mm.

I picked up a 14 lb steel flywheel (Sachs NFW1006, 1988+ transverse 60-degree V6 application) to replace the Fidanza flywheel. That will bring my clutch/flywheel assembly up to 28.72 lbs total. With the 7 lb Fidanza flywheel it would have been 21.72. The difference is not all that significant numerically and I never noticed a difference in performance anyway. The overall weight reduction was nice though.

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Sun Jan 06, 2013 3:35 pm

by Shaun41178(2)

my aftermarket aluminum flywheel came with slightly longer bolts then a factory steel flywheel bolt for the 2.8. No problems here, but I haven't put any drive time on mine so not a fair comparison.

Glad to hear it was nothing major though.

I was thinking, you have it all out, maybe swap to a 3500? Roughly same power but weighs less.

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Sun Jan 06, 2013 5:44 pm

by Series8217

Shaun41178(2) wrote:

I was thinking, you have it all out, maybe swap to a 3500? Roughly same power but weighs less.

You can't have a 3500 in California with a manual transmission. GM never certified such a configuration to emissions requirements.

And besides that, I was hoping to not even have to pull the drivetrain before selling the car, let alone doing another engine swap. I just want to sort the suspension and move on.

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Mon Jan 07, 2013 3:20 am

by The Dark Side of Will

Series8217 wrote:There are rings of compressed aluminum under where the heads of the bolts meet the flywheel. I suspect the aluminum cold flows under the bolt heads. A steel spreader plate would likely fix that problem.

I measured the Fidanza flywheel and it's 1mm thicker than the stock steel flywheel where the bolts go through, leaving about 11 mm of thread engagement instead of 12 mm.

Yes, aluminum creeps under stress, especially at elevated temperatures. I've wondered about this with regard to aluminum flywheels for quite some time. I've never heard of an OEM using an aluminum flywheel. I assume that since you bought a stock replacement, you're not going back to the aluminum unit.

I traded Alan Johnson at CHRF some Northstar blocks for cams, sprockets and a Shelby flywheel/clutch kit. The Shelby flywheel is billet steel and not aluminum... in a car built to be light weight and high performance.

That's why aluminum wiring for buildings doesn't work... as the aluminum creeps under the screw heads at a connection to a switch or outlet, the resistance of the connection increases. The increased resistance increases the temperature, which increases the rate of creep. Eventually the connection can get hot enough to start and electrical fire. This has happened.

I don't remember if the flywheel bolts are 10mm or 12mm. The diameter of the bolt is the minimum safe thread engagement in steel, for a high tension fastener like a flywheel bolt.

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Mon Jan 07, 2013 8:24 am

by Shaun41178(2)

I am pretty sure that 03,04 cobras came from the factory with aluminum flywheels

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Mon Jan 07, 2013 9:27 am

by Series8217

The Dark Side of Will wrote:I don't remember if the flywheel bolts are 10mm or 12mm. The diameter of the bolt is the minimum safe thread engagement in steel, for a high tension fastener like a flywheel bolt.

They're M10x1.0x23mm.

Shaun41178(2) wrote:I am pretty sure that 03,04 cobras came from the factory with aluminum flywheels

They did, and apparently they're not free of

problems, and Ford also discontinued the parts.

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Mon Jan 07, 2013 9:42 am

by The Dark Side of Will

Series8217 wrote:They're M10x1.0x23mm.

They did, and apparently they're not free of

problems, and Ford also discontinued the parts.

Then 11mm of thread engagement into the cast iron crank flange is fine.

Yeah, aluminum has its uses, but diveline components ain't it. (Well... except for driveshafts, but even then only in specific circumstances).

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Mon Jan 07, 2013 10:07 am

by Aaron

I've had problems with my clutch ever since I've had this car together. First with the Spec Stage 3+, and now with the Clutchnet red. Basically about half the time the clutch will slip in any gear as soon as the cams and boost come on. The other half of the time it'll hold full boost to redline in 4th. My rear main seal is leaking, has since this motors first start, and I'm thinking its splashing oil onto the flywheel/clutch, causing my slipping. Other than this I have no indication the flywheel is loose, besides it not liking high RPM gear changes (I've heard this is typical for the 282 though).

If I had the motivation I'd drop the cradle, fix the oil leak, inspect and re-torque the bolts/clutch, and put it back together. But I lack the motivation.

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Mon Jan 07, 2013 11:13 am

by Series8217

Aaron wrote:I've had problems with my clutch ever since I've had this car together. First with the Spec Stage 3+, and now with the Clutchnet red. Basically about half the time the clutch will slip in any gear as soon as the cams and boost come on. The other half of the time it'll hold full boost to redline in 4th. My rear main seal is leaking, has since this motors first start, and I'm thinking its splashing oil onto the flywheel/clutch, causing my slipping. Other than this I have no indication the flywheel is loose, besides it not liking high RPM gear changes (I've heard this is typical for the 282 though).

If I had the motivation I'd drop the cradle, fix the oil leak, inspect and re-torque the bolts/clutch, and put it back together. But I lack the motivation.

I don't think your problem has anything to do with the flywheel being loose. I haven't had any clutch problems that were coincident with the flywheel being loose, except abnormal noises.

I do have a problem with the clutch re-engaging at 6500+ RPM, but a user on the other Fiero forum reported the same problem when using the stock pressure plate with a Clutchnet disc, so I don't think it has anything to do with the flywheel.

By the way is your Clutchnet the 6-puck one? That's what I just pulled out of my car and it had already eaten the flywheel down to the bolts and wore a massive channel into the pressure plate. I think I have only 2000 miles on the car since I put it in. The friction material is extremely abrasive on iron, and the Fidanza flywheel's steel insert is not very thick by comparison. If you're slipping it at all, you'll probably need to do a replacement soon anyway. Just invite some friends over and have a drivetrain pulling party...

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Mon Jan 07, 2013 7:08 pm

by Aaron

Series8217 wrote:Just invite some friends over and have a drivetrain pulling party...

This is normally what I'd do, except I don't want to hahaha. I can't really explain why, just really lost all motivation to work on this car. It's sad really, because it has so much potential to be a truly fantastic car. I've got the gray interior in, and the interior is in excellent condition. The engine is still running perfectly, and my God is it quick (Obviously when the clutch hooks up).

I guess a lot of it is financially I'm doing well enough that I can afford nice cars, that offer the acceleration of the Fiero, along with the luxuries of modern-day cars, and handling that is not terrifying. My Fiero will walk away from my SRT8, but the SRT8 does so much more that I'd choose it every time.

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Sat Nov 04, 2017 11:59 am

by Shaun41178(2)

So major bump to this.

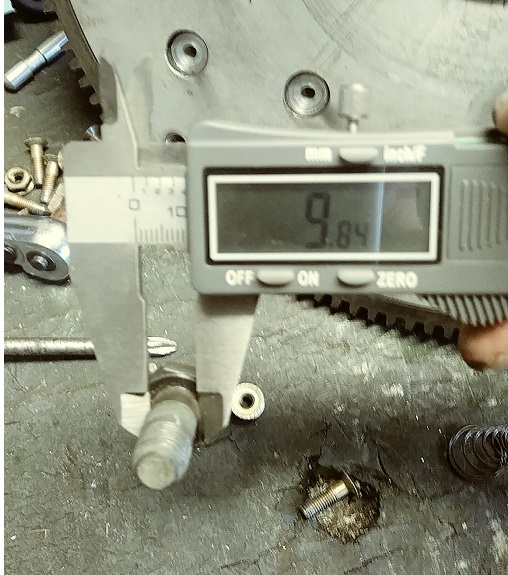

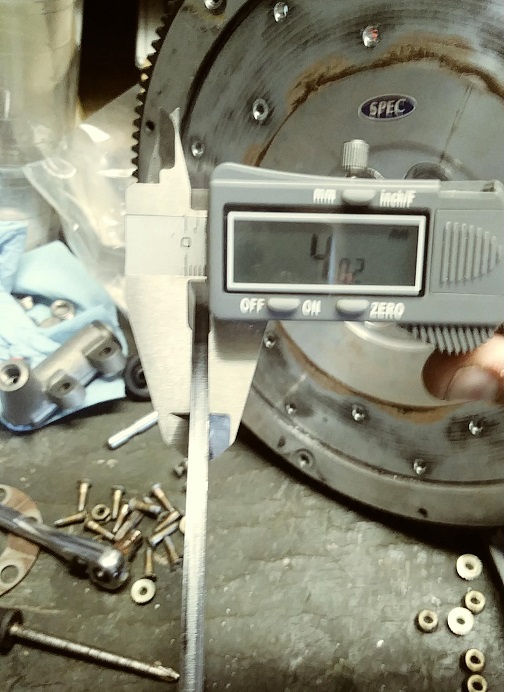

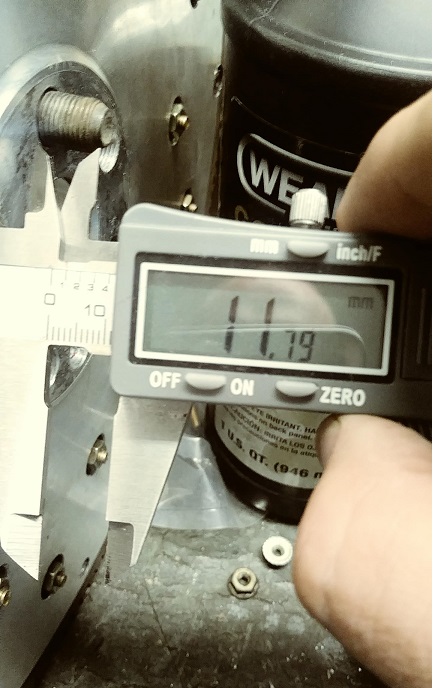

I have installed an aluminum flywheel. I bought it second hand and it is a spec. I used the factory bolts that were in the 2.8 with this. pics will show length of these. I had an issue with the bolts back out. Once I didn't use Loctite. Flywheel started rattling after a few hundred miles. I used Loctite blue the second time and they still came loose. One backed out far enough to keep the clutch from disengaging. So I pulled it out again. I am examining options based on this thread to keep it from happening again. I am posting up pics of measurements I have taken. I can prob get a longer bolt than what I have and maybe even the 29mm ford bolt once I do the math.

I did check depth of the crank and its approx. 20mm. I will say its 19 to give me a mm of extra length for bolt stretch.

here are the pics.

- 20171104_171559_Film2.jpg (113.32 KiB) Viewed 2699 times

- 20171104_165836_Film2.jpg (105.84 KiB) Viewed 2699 times

- 20171104_165818_Film2.jpg (126.28 KiB) Viewed 2699 times

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Sat Nov 04, 2017 12:02 pm

by Shaun41178(2)

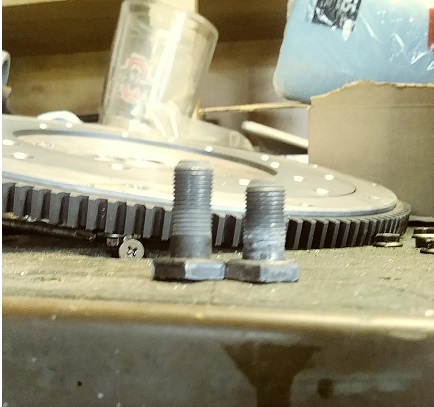

Bolt on left is 27 mm long. One on the right is 23mm. The one on left appears to be a gm bolt. Perhaps gm made them longer for the lx9 than previous years. Not sure

- 20171104_165431_Film2.jpg (70.37 KiB) Viewed 2699 times

- 20171104_165606_Film2.jpg (134.74 KiB) Viewed 2699 times

- 20171104_173049_Film2.jpg (85.26 KiB) Viewed 2699 times

'I am looking at some arp hardware washer type dealie to install on the flywheel. Not sure if it will help but I need to do some math first.

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Sat Nov 04, 2017 12:11 pm

by Shaun41178(2)

This how far a bolt has to come out to contact an unsprung clutch hub spec 5

- Message_1509151747604.jpg (116.8 KiB) Viewed 2698 times

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Sun Nov 05, 2017 4:18 am

by fieroguru

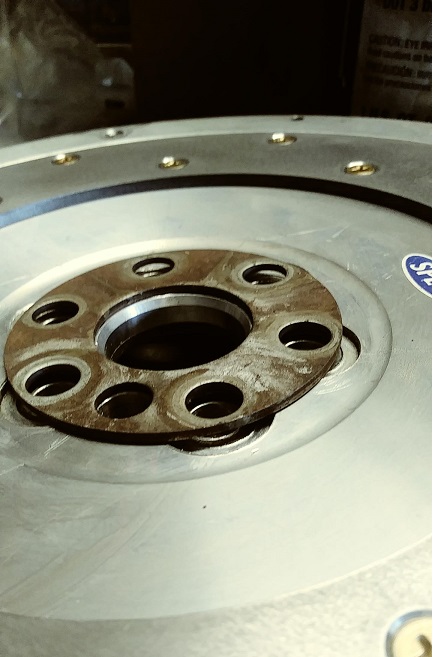

In your first pic, you can see where the aluminum was flowing out from under the small contact ring on the bottom side of the bolt head You want this contact area to be as wide as possible on aluminum, so you might try using some flanged head bolts like this.

https://www.mcmaster.com/#98093a624/=1a4gnue

The length and pitch might need adjusted and you will need to check for clearance between the bolt head and the clutch disk. There are also some on ebay with a shallower head (9.1 tall, 21.8mm flange vs. the 10.4mm and 22.3mm of the mcmaster bolts).

I would do some math and compare the clamp area of the current bolts with the small ring (area of head bolt ring - area of bolt hole) vs. the bolt options above. You will likely see a 3x+ improvement.

The longer bolt looks stretched, but that might have been vibration wear as it was bouncing around in the threaded hole once it came loose.

My aluminum flywheel on my LS4 has been tight from the initial torquing 4+ years and 43K miles ago. I used factory LS crankshaft bolts, which are a flanged head design and do a great job of spreading the clamp force to a much larger area. There is a picture in this link:

https://www.amazon.com/Performance-Flyw ... B00TO6ETNU

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Sun Nov 05, 2017 4:37 am

by Shaun41178(2)

I should have captioned my pics but I didn't but ill go back and edit.

The two bolts are different lengths. No stretch. The shorter one was what was originally on my stock 2.8. I reused them on my 3.4 turbo setup and now with my 3.5 with the aluminum flywheel.

The longer bolt is what came with the spec flywheel but I reused the factory ones but now I have learned the aluminum flywheel is thicker at the mounting flange so I need a longer bolt.

I measured the depth of the crank for the flywheel bolts at a safe 19 mm. Its an lx9 crank so it might be drilled deeper than previous iron head cranks. Series measured the thickness of the aluminum flywheel so ill add that to 19 plus the thickness of a washer. I might be able to use the 29 mm pinto bolts and if not the 25s should work

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Tue Nov 07, 2017 2:03 am

by The Dark Side of Will

A bolted joint utilizes the full strength of the bolt when the engaged length of threads equals the diameter of the bolt. More engaged length than that is not necessary. Pick your bolt length based on that standard. Put it back together with steel washers in the counterbores, but be sure you put the ROUNDED corner of the washer into the counterbore and leave the sharp corner exposed.

Re: 60* V6 Fidanza Aluminum Flywheel

Posted: Tue Nov 07, 2017 3:26 pm

by Shaun41178(2)

I went down to my local ACE and picked up some washers. Grade 8 7/16 washer. The ID was an 80s cunt hair too small, but a sanding roll and 5 minutes got them all the correct size. They are 1.92mm thick, which pretty much makes them flush with the top of the counterbore.

With the washer in place, the 27mm bolt now has about 11mm of depth into the crank.

- 20171107_201849_Film2.jpg (120.59 KiB) Viewed 2671 times

- 20171107_201914_Film2.jpg (154.01 KiB) Viewed 2671 times

- 20171107_202026_Film2.jpg (105.3 KiB) Viewed 2671 times