Well im expecting 600hp+ but 800 doesnt seem impossible. Iknow Ineed

to step up the inj. just been seeing what it can do..

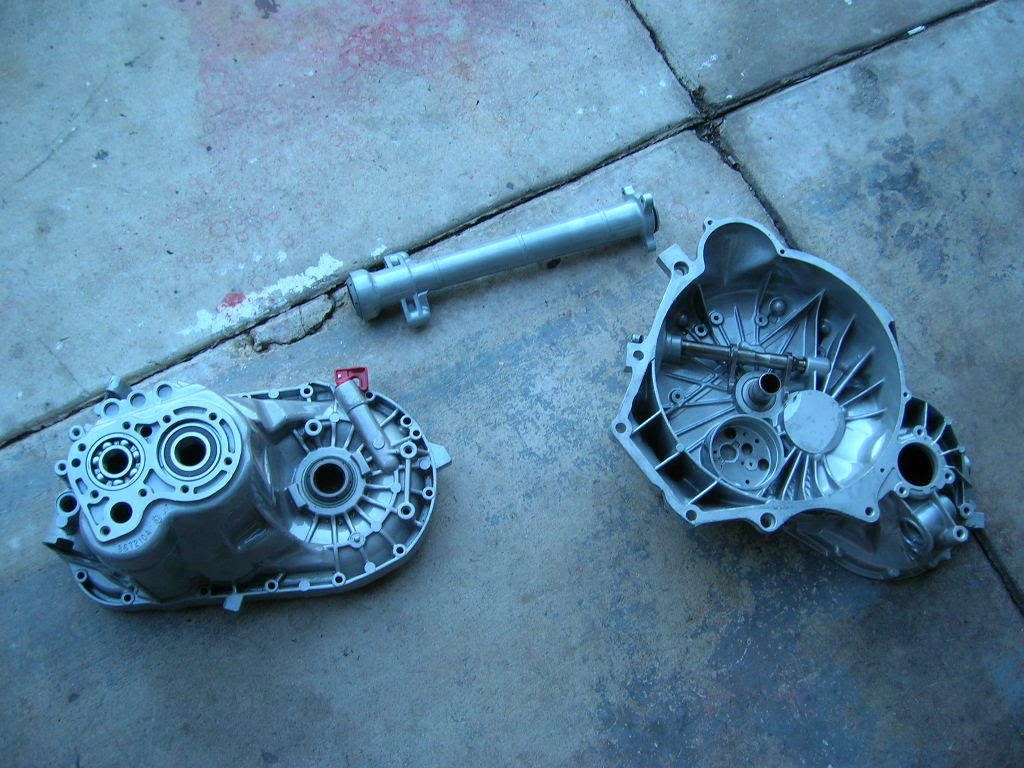

Ive done alot of reading up on FWD tranny failures, getrags in particular

and I thing the 2 factors in them failing ( the diff coming out) is the shim

is work out, and the diff has some play to get off center line and the

other is the stock (long ass) axle. with lots of tourqe the 2 tripod cups and

bind and lock up. So the whole thing wants to rotate in an out of round

circle, causing the diff to come out of the case.

Im hoping the jackshaft will help stablize the diff and keep in the center

line with the gears. I also looked into DSM and about 600hp or so the

case spreads and cracks (the gear clusters pushing each other apart

enough to break the case) with that in mind I made the brace, also there

is another 3/8 plate that goes over the end, for the 2 bearing clusters.

If you havent noticed Im a mechanical eng. that over builds every thing

and try to anticipate failer points. And sometimes go over board... ha ha

So far I can roll on boost in 3rd gear and break the tires lose, and no

failures to report as of yet, so Im not sure how much further I can really

expect it to go.

Im running a spec stage 3+. they say it can hold 560ft/lb and seems be a

very streetable! and holding, I think. It hard to tell my tires dont squeal

anymore

And my crank was balanced seperatly from the balancer, flywhel and

pressure plate, its a findanza by the way, and was 4g off. the balancer

was 6g and the pressure plate was dead on! :blah5: ha ha