Improving suspension geometry?

Moderators: The Dark Side of Will, Series8217

Re: Improving suspension geometry?

An issue that Series8217 raised was the total amount of camber needed in a turn. While we measure caster over a 40* range of motion, it's very unlikely you'll ever need 20* of steering angle for any turn- more like 10*.

Anyone know how to calculate the radius of a turn based on steering angle, or conversely what steering angle will you need for a given radius turn? I know it's a function of the wheelbase.

Anyway, let's assume a corner requiring 10* steering angle, and generating 1.0 g lateral force. Based on the springs and ARB on my car, the car will roll 1.15*, which translates to 1.15".

Based on the chart I posted earlier, I would need -1.2* static negative camber to achieve slightly over 3* negative camber at 1" compression and 10* steering angle. Why 3*? Because that's what Hoosier said the A6 tires like. Now they didn't give any more information. They just said A6's like lots of camber about 3*. But what does that mean? I'm guessing it's the amount of camber necessary for the lateral thrust of the sidewalls. (I don't know if that's the correct term).

Now another tire may need more or less camber. So Series8217 is setting his car up for lots of negative camber, but he's using "street" tires, which may require even more camber.

Does this seem logical?

Anyone know how to calculate the radius of a turn based on steering angle, or conversely what steering angle will you need for a given radius turn? I know it's a function of the wheelbase.

Anyway, let's assume a corner requiring 10* steering angle, and generating 1.0 g lateral force. Based on the springs and ARB on my car, the car will roll 1.15*, which translates to 1.15".

Based on the chart I posted earlier, I would need -1.2* static negative camber to achieve slightly over 3* negative camber at 1" compression and 10* steering angle. Why 3*? Because that's what Hoosier said the A6 tires like. Now they didn't give any more information. They just said A6's like lots of camber about 3*. But what does that mean? I'm guessing it's the amount of camber necessary for the lateral thrust of the sidewalls. (I don't know if that's the correct term).

Now another tire may need more or less camber. So Series8217 is setting his car up for lots of negative camber, but he's using "street" tires, which may require even more camber.

Does this seem logical?

Re: Improving suspension geometry?

Formula for turning diameter:

Diameter=2 X wheelbase/sin(x)

x=steering angle.

So Diameter of 10* steering angle= 2 X (93/.174)= 89 feet

Diameter of 15* steering angle= 60 feet

Diameter of 20* steering angle= 45.4 feet

Hmmm.

Does this look right?

Diameter=2 X wheelbase/sin(x)

x=steering angle.

So Diameter of 10* steering angle= 2 X (93/.174)= 89 feet

Diameter of 15* steering angle= 60 feet

Diameter of 20* steering angle= 45.4 feet

Hmmm.

Does this look right?

- Series8217

- 1988 Fiero Track Car

- Posts: 5981

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: Improving suspension geometry?

You're running a 23" tire? I'm surprised you have any ground clearance.bse53 wrote:The floor to center of the hub is 11.5".Alternatively, you could measure from the floor to the height of the center of the hub, post that number, and continue quoting "chassis height" as you have been... although you'll have to be more specific about what you're measuring to when you quote chassis height. Knowing your hub height will give us a basis of comparison.

Where are you measuring the chassis height?

- Series8217

- 1988 Fiero Track Car

- Posts: 5981

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: Improving suspension geometry?

Thanks for the clearer picture. So for measurement purposes you have adjusted the block under the shock mount to set the suspension at the desired ride height relative to the chassis?

Re: Improving suspension geometry?

Thought I was making progress adapting the Koni 30's. I used the original Carrera shocks to center the shock in the spring. Everything looked good.

Cut the old shock mount and welded it to 1.5" piece of 3" pipe. Then cut the pipe to follow the contour of the shock mount.

Then tacked it to the car.

But it won't work. The Koni's are a larger body (50mm?) and longer. Also the Koni's default to extended (because they're gas charged monotubes?).

So now I'm back to square one. I didn't want to try and make a mount using the eye top, since this mount barely clears the UCA in its rearward position, but I don't have a choice now.

I meant to make the pictures smaller so the quality of my welds didn't show. I've never welded before, and bought a Harbor Freight MIG welder, but using gasless wire.

Cut the old shock mount and welded it to 1.5" piece of 3" pipe. Then cut the pipe to follow the contour of the shock mount.

Then tacked it to the car.

But it won't work. The Koni's are a larger body (50mm?) and longer. Also the Koni's default to extended (because they're gas charged monotubes?).

So now I'm back to square one. I didn't want to try and make a mount using the eye top, since this mount barely clears the UCA in its rearward position, but I don't have a choice now.

I meant to make the pictures smaller so the quality of my welds didn't show. I've never welded before, and bought a Harbor Freight MIG welder, but using gasless wire.

Re: Improving suspension geometry?

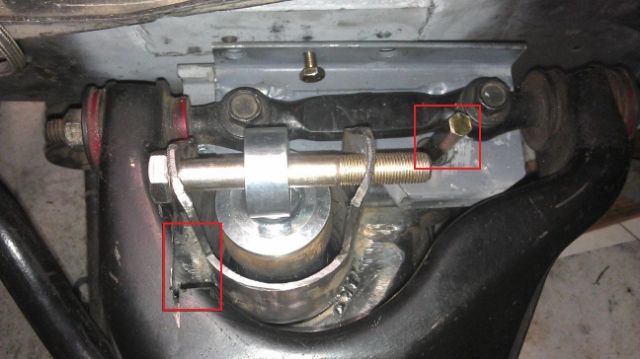

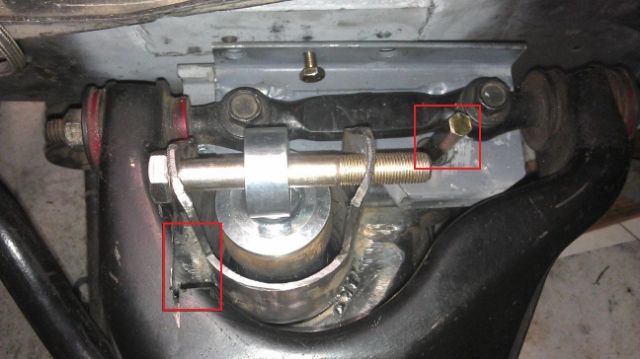

Well, after several unsuccessful attempts I think I got the Koni 30's mounted with the bracket I made to move the UCA mounting points rearward.

It's an extremely tight fit. The problem trying to use the Koni's is the extra length and size of the shock body. With the arc of the LCA, there is about 1/4" range of mounting position so the shock body will clear the opening in the mounting frame inboard when the tire is in droop and not rub on the other side when in compression.

If I had to do it over I would look for a shock with 36mm body-- like Bilsteins.

As you can see I had to notch the UCA. I don't think there's enough load on the UCA, since all the load is between the LCA and upper spring 'perch'. What do you think?

The other box shows the hex key I use to adjust the UCA for caster/camber. You can see how much I moved the mounting rearward.

It's an extremely tight fit. The problem trying to use the Koni's is the extra length and size of the shock body. With the arc of the LCA, there is about 1/4" range of mounting position so the shock body will clear the opening in the mounting frame inboard when the tire is in droop and not rub on the other side when in compression.

If I had to do it over I would look for a shock with 36mm body-- like Bilsteins.

As you can see I had to notch the UCA. I don't think there's enough load on the UCA, since all the load is between the LCA and upper spring 'perch'. What do you think?

The other box shows the hex key I use to adjust the UCA for caster/camber. You can see how much I moved the mounting rearward.

- Series8217

- 1988 Fiero Track Car

- Posts: 5981

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: Improving suspension geometry?

Yeah... that's why I suggested the Bilsteins. Konis don't give you any room to work with. You can't modify the bodies or shafts because Koni wont sell you parts. In my other thread I identified some 36mm body Bilsteins that bolt right into an '88 Fiero. They cost ~$120 new for the pair and $100 each to be revalved for your springs and corner weights.

I would smooth out and radius that notch. You've added "tear here" marks to the control arm. Looks scary.

I would smooth out and radius that notch. You've added "tear here" marks to the control arm. Looks scary.

Re: Improving suspension geometry?

They probably would have been a better choice, but the Koni's are adjustable in rebound, and they were $132 from Jegs.

After tacking it and then cutting it, I got everything to work (I was worried the body was rubbing in compression). I've abandoned my adapter for moving the mounting points back for now. As you can see, everything fits nicely. I'll have to weld a piece on the UCA where I notched it.

I did increase the adjusting slots, so I'm getting 2* of static camber and 6* of caster, which is much better than it was. I do think with the amount the car has been lowered, raising the mounting points is still an advantage. When I get around to building the UCA's Series 8217 fabbed up, I'll probably raise the mounting points then.

One side done, get the other side soon and move on to the transmission-- the next AX is May 23-24, I think, so I've still got a lot of work.

Re: Improving suspension geometry?

Sorry to jump in, but I was wondering about an anti-dive mod for the front of an '84-87. I did a search but didn't get anything. Has anyone built/tested something?

-

ericjon262

- Posts: 2831

- Joined: Mon May 24, 2010 5:34 pm

- Location: Aiken, SC

Re: Improving suspension geometry?

mender wrote:Sorry to jump in, but I was wondering about an anti-dive mod for the front of an '84-87. I did a search but didn't get anything. Has anyone built/tested something?

Will has, it's in his build thread

http://realfierotech.com/phpBB/viewtopi ... ti#p145235

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

-

ericjon262

- Posts: 2831

- Joined: Mon May 24, 2010 5:34 pm

- Location: Aiken, SC

Re: Improving suspension geometry?

mender wrote:Thanks!

No problem, if you make a set, PM me, I would be interested in one myself.

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

-

The Dark Side of Will

- Peer Mediator

- Posts: 15630

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Improving suspension geometry?

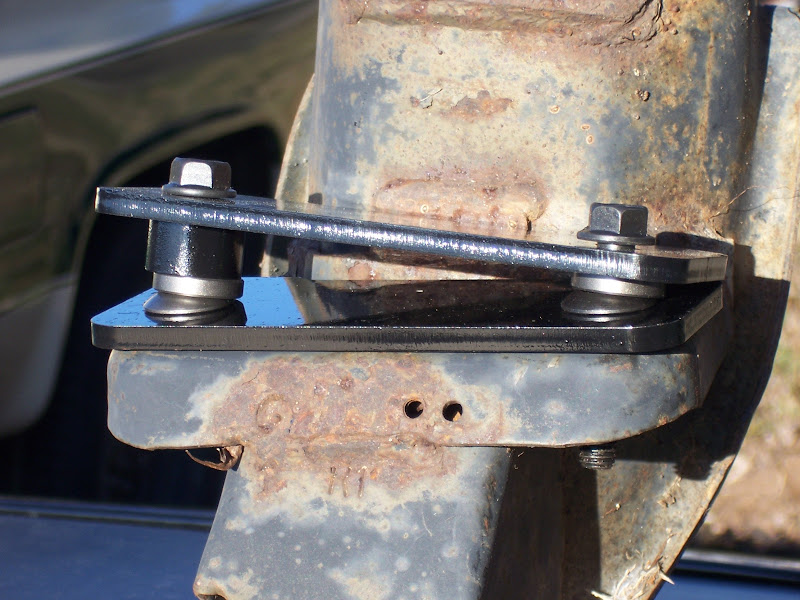

They work GREAT, but the presentation shown in that thread needs some refinements before it's ready for "prime time".

Mostly, there need to be locating shoulders at every interface, making sure that the stack stays straight and concentric, as well as being located correctly in the "counterbore" where the crossmember bolts to the body. As shown, there's room for the crossmember to "squirm" as you tighten the bolts.

Mostly, there need to be locating shoulders at every interface, making sure that the stack stays straight and concentric, as well as being located correctly in the "counterbore" where the crossmember bolts to the body. As shown, there's room for the crossmember to "squirm" as you tighten the bolts.

-

The Dark Side of Will

- Peer Mediator

- Posts: 15630

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Improving suspension geometry?

ATS modular spindles: http://www.speedtechperformance.com/ind ... prd136.htm

Build your own steering arm, ZR1 hubs and Corvette brakes. Standard height might work well in a re-imagined Fiero front end.

Seen in application here: http://forums.corner-carvers.com/showpo ... stcount=77

Build your own steering arm, ZR1 hubs and Corvette brakes. Standard height might work well in a re-imagined Fiero front end.

Seen in application here: http://forums.corner-carvers.com/showpo ... stcount=77

- Series8217

- 1988 Fiero Track Car

- Posts: 5981

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: Improving suspension geometry?

I contacted Speedtech about the dimensions of those knuckles earlier this year and never heard back. We need to know the total spindle height (distance between ball joint mounting faces), distance between the lower balljoint and the hub axis, distance between the hub face and the steering axis, and the kingpin angle (angle between the steering axis and hub axis). They make them in two heights; "factory height" and "tall". They are for A-F-X body cars and both heights include a one inch drop from stock.

I found these curious notes in the installation instructions:

I found these curious notes in the installation instructions:

All aluminum has an endurance limit. Therefore, it is recommended to replace

spindles every 15 years or 225,000 miles as a precautionary measure.

Speedtech uses special jigs to install ZR1 hubs into our ATS spindles. Should

your hubs ever need servicing, it is recommended you ship the spindles to us so

that we can use the same process we used to originally build them. Servicing

them other than through Speedtech Performance will waive any implied or

expressed liability for the hub and/or spindle.

-

ericjon262

- Posts: 2831

- Joined: Mon May 24, 2010 5:34 pm

- Location: Aiken, SC

Re: Improving suspension geometry?

I wonder why the hub requires a jig to be installed?Series8217 wrote:All aluminum has an endurance limit. Therefore, it is recommended to replace

spindles every 15 years or 225,000 miles as a precautionary measure.

Speedtech uses special jigs to install ZR1 hubs into our ATS spindles. Should

your hubs ever need servicing, it is recommended you ship the spindles to us so

that we can use the same process we used to originally build them. Servicing

them other than through Speedtech Performance will waive any implied or

expressed liability for the hub and/or spindle.

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

- Series8217

- 1988 Fiero Track Car

- Posts: 5981

- Joined: Thu Jun 02, 2005 9:47 pm

- Location: Los Angeles, CA

Re: Improving suspension geometry?

Right?

And how did they determine the 225,000 mile service life? I would imagine a real OEM part is designed to last an unreachable service life like 500,000 or 1,000,000 miles at least...

And how did they determine the 225,000 mile service life? I would imagine a real OEM part is designed to last an unreachable service life like 500,000 or 1,000,000 miles at least...

-

ericjon262

- Posts: 2831

- Joined: Mon May 24, 2010 5:34 pm

- Location: Aiken, SC

Re: Improving suspension geometry?

well, that's probably just making sure their asses are covered, and let's face it, how many people will put that many miles on a car that's got $1000 just in the spindles...Series8217 wrote: And how did they determine the 225,000 mile service life? I would imagine a real OEM part is designed to last an unreachable service life like 500,000 or 1,000,000 miles at least...

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

-

The Dark Side of Will

- Peer Mediator

- Posts: 15630

- Joined: Wed Nov 24, 2004 11:13 pm

- Location: In the darkness, where fear and knowing are one

- Contact:

Re: Improving suspension geometry?

ericjon262 wrote: I wonder why the hub requires a jig to be installed?

Maybe it has something to do with the location of the third hub bolt...Series8217 wrote:Right?

It looks like they have to drill the threads out of the mounting flange, drill an access hole through the wheel flange and put a bolt through from the wheel side; IOW, trying to modify your own ZR1 hubs to do that wouldn't be a great idea for a lot of people.

Hard to tell if it's a bolt head or a nut on a stud... either way that hole in the hub cartridge has to be drilled out.

A WAG based on a BOTEC level FEA, probably. I'm confident a Corvette can be driven a million miles and not need new knuckles.Series8217 wrote: And how did they determine the 225,000 mile service life? I would imagine a real OEM part is designed to last an unreachable service life like 500,000 or 1,000,000 miles at least...