I measured the stock intake and I came up with a measurement of 9-1/4 inches from the base of the lifter valley of the block, to the top of the upper intake manifold. I then measured from the top of the upper intake to the botoom of the decklid and I got around 3 inches or so.

This means from the block to the decklid is about 12 inches or so. Now I want to play it safe for engine movement or anything else I might mismeasure which brings me down to about 11 inches for a total height of the intake I can run and still fit under a stock decklid.

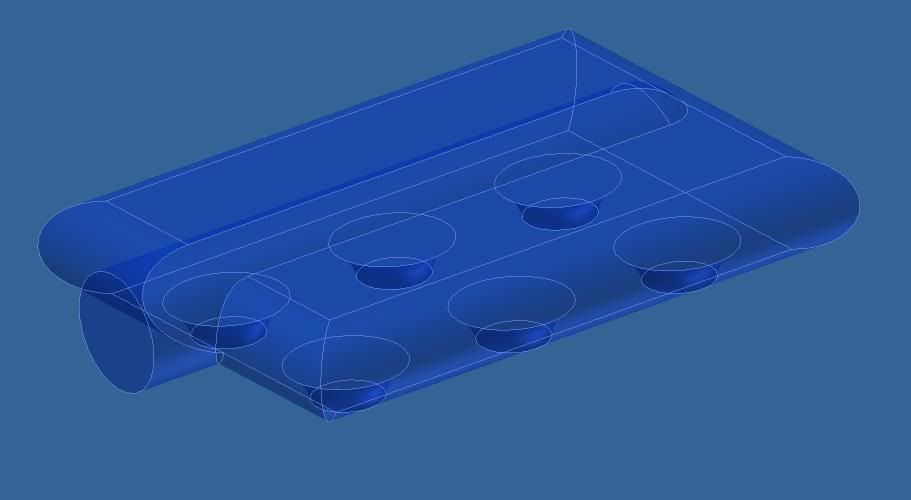

I would like to turbocharge this itb intake which would mean I would have to build a plenum box. Now I could probably build 2 of them one for each bank, but I think a single large one would be easier and have more consistent flow between the banks of cylinders as well.

This is what I am working with so far.

Thats 2 inches of runner right there under my mocked up cardboard peice. That leaves me 2.5 inches above that point to allow for the fead from the turbo and still clear the decklid. Where that carboard peice is is about as high as I can go with it if I was to have the plenum be 2.5 inches high. Basically I don't want the air to have to take a hard 90 degree turn to find its way into the runner, which is why I want some height to my plenum.

With the intake, the runner and the 2.5 inches height for the plenum, this would put me at a total of 11 inches from the base of the lifter valley.

This would give me abuot a total of 3 inches from the plenum, to the throttle body blade inside the runner. Talk about a short ass runner

Questions I have.

1. Someone please help me choosing the volume for this plenum. its to feed 3.5 liters with a camshaft around .430 lift and a 114 lsa or so. Basically its a stock 3400/3500 cam. Also with a runner length from the plenum to the blade about 3 inches and to the valve about another 3 inches.

2. How screwed am I with this runner length with the cam I am running? I am pretty sure this is a low to midrange cam from GM and this is a short runner intake. Not designed to work well with each other from the reading I have done.

I can take more pics if need be.

Thanks