pmbrunelle wrote: ↑Fri Oct 22, 2021 12:22 pm

V-bands seem to be the kind of thing that could be standardized and made interchangeable, but they're not...

That would definitely make things easier, that being said, the V band I thought I had ordered was also a different size, 2-1/4 VS 2-3/8

_________________________________________

I've worked almost every day this month, the overtime makes for awesome paychecks, but not much time for anything else, over the past 2 days I whittled a bolt on bolthole out of 6061 on the mill at work, I'm still learning my way around the mill, I know enough to be dangerous, but not enough to make nice looking part, so I sandblasted it to hide the toolmarks.

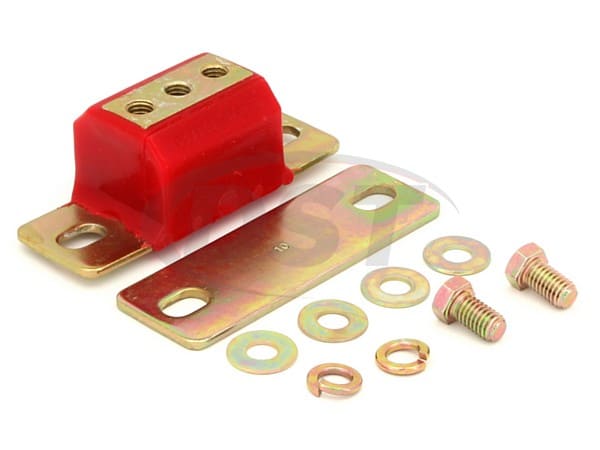

This part replaces a spacer installed between the AC compressor, and the block, and will allow me to make a much better tensioner mount. Next, I'll make a plate that bolts on in the red circled holes. I wanted to use the threaded idler boss on the timing cover (blue circle) but unfortunately, it just won't work out, so I'll mount the tensioner somewhere in the yellow circled area. The idler boss will be ground off.

here's a shot of the tensioner on the idler boss, it gives an idea of the placement, and how the belt routing should work. it's unfortunate I can't put it right there, the problem is an issue with the anti rotation pin than anything else, installed here, the pin would need to occupy the same space one of the timing cover bolts. The tensioner itself came from the XFI cobalt I got the FY1 trans for the Gran Damn from.

overall, this new tensioner setup will be stronger, a overall simpler design, and should allow me to eliminate an idler near the alternator. I'm hoping it's also lighter, parts that were steel are now aluminum, but they're also bigger, and the tensioner itself is more massive. The two timing cover bolts, and the new bolt will be flatheads, countersunk so they maintain adequate clearance to moving parts. I'm hoping to finish it up tomorrow.

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."