Brake Rotor Machining?

Moderators: The Dark Side of Will, Series8217

Brake Rotor Machining?

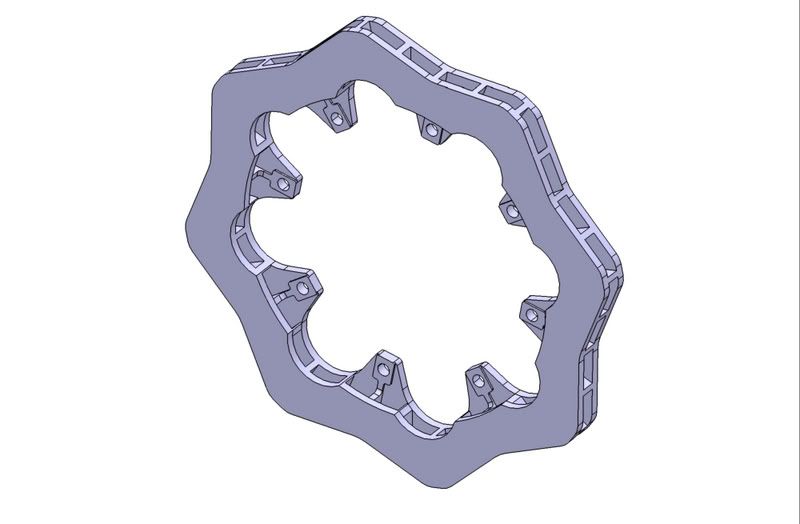

I've been thinking about ways to reduce unsprung weight. A scalloped rotor comes to mind. I can get a regular rotor for $30, or I can pay $100 for basically the same rotor that's been scalloped.

So keeping this in mind, I've found out that I'll likely have on-and-off access to a 3-axis CNC mill on weekends this summer.

So my next concern is how the rotor will react to being machined. Obviously it would need to be properly fixtured etc and maybe balanced afterwards. But does anyone know what kind of heat treating or post processing a rotor goes through after it's cast? I've been searching for quite some time, and I can't really find any details on that kind of thing. I'm doing good to even find what type of cast iron the manu's use.

So, anyone have any insights?

I'm probably going to call a couple of brake manu. tech lines and get some opinions there too.

Thanks!

Nate

So keeping this in mind, I've found out that I'll likely have on-and-off access to a 3-axis CNC mill on weekends this summer.

So my next concern is how the rotor will react to being machined. Obviously it would need to be properly fixtured etc and maybe balanced afterwards. But does anyone know what kind of heat treating or post processing a rotor goes through after it's cast? I've been searching for quite some time, and I can't really find any details on that kind of thing. I'm doing good to even find what type of cast iron the manu's use.

So, anyone have any insights?

I'm probably going to call a couple of brake manu. tech lines and get some opinions there too.

Thanks!

Nate

Last edited by Indy on Wed Feb 14, 2007 5:24 pm, edited 1 time in total.

Indy DOHC Turbo SD4.....someday.

Oh, and f*ck the envelope. (RFT Insurgent)

Oh, and f*ck the envelope. (RFT Insurgent)

-

Boscolingus

- Posts: 448

- Joined: Sat Dec 16, 2006 8:38 pm

- Location: Valencia, CA

-

Boscolingus

- Posts: 448

- Joined: Sat Dec 16, 2006 8:38 pm

- Location: Valencia, CA

not anymore than slotted or drilled.Boscolingus wrote:I am by no means a rocket scientist - or any scientist for that matter, but wouldnt that just wear the shit out of the pads? Interesting idea though

I would think finding the amount of braking required, and shrinking the rotor to that point would be better. being, that small diameter increases make for quite a material increase - and material increase is weight increase. but, I am also scared of the pulsing effect of the variable diameter - but DAMN that looks cool.

-

p8ntman442

- cant get enough of this site!

- Posts: 3289

- Joined: Wed Mar 30, 2005 2:37 pm

-

Boscolingus

- Posts: 448

- Joined: Sat Dec 16, 2006 8:38 pm

- Location: Valencia, CA

they reduce gas build up no more that slotted rotors but have ~30% less surface area - this will reduce pad life.

but like you said the reason to di it isn't for pad life - its to lose rotating mass.

i'd rather put the effort into lighter rims. but to be honest i'm not serious enough driver that scalloped rotors would improve my track times at all.

but like you said the reason to di it isn't for pad life - its to lose rotating mass.

i'd rather put the effort into lighter rims. but to be honest i'm not serious enough driver that scalloped rotors would improve my track times at all.

-

cactus bastard

- Posts: 290

- Joined: Wed Aug 16, 2006 12:14 pm

- Location: Alberta

Why don't you use aluminum bells / hats, and then just use an off the shelf wilwood rotor? They aren't very expensive, plus you'd drop some more unsprung weight, and raise the cool factor even more. You can use your CNC to machine yourself some nice caliper brackets instead. (you can even make me some too)

Why would you eat bad ice cream?

I occasionally machine aluminum and steel tooling and fixtures on a POS manual mill where I work. The CNC that would be available has a pretty good coolant system. I don't think I'll have to worry about heat damage, I was more concerned about imparting other stresses to the rotor by machining, and was curious of rotors went through any stress-relieving processes after they've been machined by the manu.

The new rotors would yield a rotational MOI of around 66lb-in^2. Unmachined rotors would yield an MOI of around 100lb-in^2. I'd say these numbers are + or - around 10lb-in^2, since I don't have drawings of vanes profiles. That's a pretty good decrease for a 28% reduction in surface area and about 35% reduction in mass.

But really what I'm going after is a reduction in raw unsprung weight. I'm looking into this because the calipers on the way are a little bit heavier than I would've liked (5.2lbs each, ouch). But, they DO use a 4.75" long pad, which I'm hoping will help with the lower SA of the rotor.

Will probably knows what this is for.

The new rotors would yield a rotational MOI of around 66lb-in^2. Unmachined rotors would yield an MOI of around 100lb-in^2. I'd say these numbers are + or - around 10lb-in^2, since I don't have drawings of vanes profiles. That's a pretty good decrease for a 28% reduction in surface area and about 35% reduction in mass.

But really what I'm going after is a reduction in raw unsprung weight. I'm looking into this because the calipers on the way are a little bit heavier than I would've liked (5.2lbs each, ouch). But, they DO use a 4.75" long pad, which I'm hoping will help with the lower SA of the rotor.

Will probably knows what this is for.

Last edited by Indy on Thu Feb 15, 2007 3:10 pm, edited 1 time in total.

Already going to use Al hats. The brake caliper bracket is fabbed steel and should weigh around .65lb.cactus bastard wrote:Why don't you use aluminum bells / hats, and then just use an off the shelf wilwood rotor? They aren't very expensive, plus you'd drop some more unsprung weight, and raise the cool factor even more. You can use your CNC to machine yourself some nice caliper brackets instead. (you can even make me some too)