D-oh! Thanks for looking.

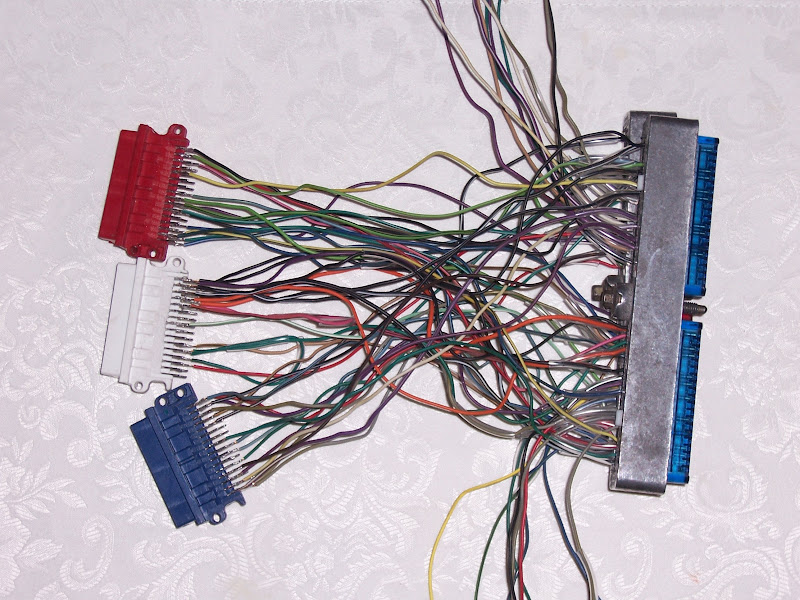

I was able to take a few hours yesterday and today to do the majority of the work on the wiring harness adapter for the Shelby PCM.

I'll come back and fix these photos:

Edit: Fixed.

The Dark Side of Will wrote:

In order to minimize the number of changes at once, I'm going to build a harness adapter in order to use the Shelby computer with my current harness. All of the following parts will have to be added to it.

Altrbo was nice enough to put his mad JDM tyte j0 NASA skillz to work and rip the connectors off a '90's Buick PCM for me. These are the same connectors used by the OBDI Caddy PCM. Sinister was able to get me a pigtail with the Shelby computer. I'll marry these up to the pigtail to make the adapter.

This is a MAF sensor connector. That should be fairly straight forward. I believe these are available through CarQuest. I'll just have to run an independent pigtail to it from the ECM harness adapter which will be inside the car with the ECM.

This is the IAC connector. That one in and of itself won't be a problem either. However, it will need to be part of a second smaller harness adapter which will adapt the ISM wiring for the '93-'95 throttle body I currently have to the IAC connector on the '96+ throttle body I'm going to use. The ISM uses what is essentially a 4 pin weatherpak, BUT the connector position assurance (CPA) clip is at one end of the connector for the ISM, while it's in the middle for the standard 4 pin weatherpack.

Once the Shelby computer is installed, tuned and has some trouble-free miles on it, I'll completely rework the harness into Northstar-Fiero Harness v. 2.0. That will change the routing to keep more wiring out of sight and possibly more the ECM to the engine bay or into the wheel house behind the quarter panel.

Edit:

The MAF connector shown above is from my dad's 400 SBC Jaguar running LT1 controls and 3 wire MAF with separate IAT. The Caddy MAF that's integrated to the OBDII throttle body has an integral IAT and therefore a 5 wire connector.

The IAC connector shown above is the one I'll need, however.

Remaining to be done:

-Populate a 3 or more pin Molex which carries a clutch switch wire, and +12V/GND for the MAF sensor from the interior body harness. Theoretically, I could have brought them off the backs of the adapter connectors, but space is at a premium when soldering to those pins, and the existing power/ground wires are 18 ga rather than 22. There just wasn't space to get everything in and allow room for the shrink tube which will be needed to assure isolation.

-Build an additional pigtail for the MAF and connect it to the aforementioned Molex as well as the signal pin on the Shelby connectors.

-Provide for a connection to the IAC, either by building an adapter to go from the ISM to the IAC or by running a dedicated pigtail similar to that which I will have to build for the MAF sensor. The ISM to IAC adapter is complicated by the fact that one of the ISM wires goes directly to ground, so I have to run one wire the entire length ANYWAY... might as well run three more and have one less connector to worry about.

-Obtain and wire in an OBDII DLC.

Once I do those things, the car will be ready for swapping the throttle to an OBDII unit and trying the Shelby PCM.

Also, the left decklid hinge pin broke, so I had to develop a replacement: