Page 26 of 75

Re: The Mule rides again (sort of) - pics.

Posted: Fri Oct 18, 2013 9:32 am

by The Dark Side of Will

Per Sinister's recommendation, I'm going to try logging a smaller number of parameters to see if that helps the junk data situation.

In looking through the PID list on Torque, I note that the equation for injector pulse width is ((A<8)+B)/65.535

That may mean 65,535, as the app was written "offshore". I'm not sure if A is the MSB and B is the LSB or what...

That seems to imply that there are two bytes of data in that PID... BUT each cylinder's pulse width PID has a consecutive address, so I would expect them to be single bytes. I can't imagine getting meaningful injector pulse width info from a single byte of data, though

It sounds like at least one of the equation and location are wrong, maybe both.

The equation for the pulse widths is ((A<8)+B)/65.535

I'm assuming this is sixty thousand five hundred and thirty five (and NOT sixty five decimal five three five).

This equation looks like adding the LSB to the results of a logical test on the MSB. Is this the correct way of interpreting that? Does < represent a bit shift, mask or other operation?

I have similar questions about the misfire counters, which are (A<8)+B

Torque shows their range to be 0 to 1000, which doesn't really jive with a logical test on the MSB.

Re: The Mule rides again (sort of) - pics.

Posted: Fri Oct 18, 2013 9:39 am

by Sinister Fiero

65535 is a valid (maximum) 16 bit value which = FFFF in hex

65.535 does not look like any divisor or multiplier I've ever seen (but just because I haven't seen it doesn't mean it isn't used).

AFAIK, the data communicated to the scanner from the PCM is going to be communicated in HEX values. The scanner must then convert the HEX value over to a usable (standard) number before it can perform any calculations to give you a valid scan data readout.

Edit to add: I suppose 65.535 could be used to scale 65535 down to a maximum reading of "1000".

Re: The Mule rides again (sort of) - pics.

Posted: Fri Oct 18, 2013 10:09 am

by The Dark Side of Will

I know 65535 is the max value for a 16 bit number. Dividing by 65535 or 65.535 really doesn't make much difference... it's only the location of the decimal point.

If A<8 means that only the 3 LSb's of the MSB are used, then the resulting 11 bit value could represent a number up to 2048, which could capture pulse widths up to 31.25 ms, with a divisor of 65.535.

However, the A<8 expression doesn't look like an attempt to turn the 16 bit number into an 11 bit number unless the < operator represents bit shifting, bit masking or some oddball operation that is NOT the "logical test of less than".

Re: The Mule rides again (sort of) - pics.

Posted: Fri Oct 18, 2013 8:12 pm

by Sinister Fiero

Were the TorquePro message forums of any help?

Re: The Mule rides again (sort of) - pics.

Posted: Mon Oct 21, 2013 3:55 am

by The Dark Side of Will

Re: The Mule rides again (sort of) - pics.

Posted: Mon Oct 21, 2013 4:21 am

by The Dark Side of Will

Does Alldata have a PID list for the Shelby?

Re: The Mule rides again (sort of) - pics.

Posted: Mon Oct 21, 2013 8:13 am

by Sinister Fiero

I have never seen a PID list (the one I think you are actaully looking for) in ALLDATA or MITCHELL on DEMAND.

All the GM service manual gives you is a general SCAN TOOL (data) DEFINITIONS list that just explains that "LTFT" is Long Term Fuel Trim and stuff like that. Seems like it is something they put together to cover ALL the vehicles they sell and isn't specifically written for any particular vehicle. I can tell you that they don't give you actual addresses for the PIDs.

The techs at HP Tuners probably know the information you are looking for but I'm betting they won't be willing to give it up since that would help the competition and not lead to you buying their scanning software.

You might try the people who were behind developing the Monodax scanner. Their forum has been down for over a year now but you might be able to reach someone thru their main site here:

http://www.monodax.com/

Re: The Mule rides again (sort of) - pics.

Posted: Tue Oct 29, 2013 6:32 am

by The Dark Side of Will

Interesting... Thanks.

Re: The Mule rides again (sort of) - pics.

Posted: Tue Oct 29, 2013 8:47 am

by ericjon262

the guys on gearhead-EFI.com have been trying to get with the people who were running monodax for quite some time now with no luck. might pick some of their minds.

Re: The Mule rides again (sort of) - pics.

Posted: Thu Oct 31, 2013 5:51 am

by The Dark Side of Will

I'll put that on the list.

Re: The Mule rides again (sort of) - pics.

Posted: Mon Nov 11, 2013 8:17 am

by The Dark Side of Will

It occurs to me that I can probably use a TECH 2 to scroll through the "official" PID's that the Shelby delivers... Putting out feelers to dealership types

Re: The Mule rides again (sort of) - pics.

Posted: Mon Dec 23, 2013 12:38 pm

by The Dark Side of Will

No dice on PID's from TECH 2.

Re: The Mule rides again (sort of) - pics.

Posted: Mon Dec 23, 2013 1:28 pm

by Sinister Fiero

The Dark Side of Will wrote:No dice on PID's from TECH 2.

Didn't think you would have any luck there, as there is no way I know of to get datastream PID address info out of a Tech 2 scanner.

Too bad you didn't live closer - I'd just have you bring the car by and I'd hook my Tech 2 up to it.

Re: The Mule rides again (sort of) - pics.

Posted: Tue Jan 14, 2014 6:04 am

by The Dark Side of Will

I sketched out the rear face heat shield for the oil pan. It actually was made quickly, to my surprise. My dad can get things cut for free on the laser cutter where he works, but since it's being made for free, we don't get to set a deadline... so getting things typically take a few weeks.

Also got it bent up and fit-checked on my mockup block. I'll integrate the two heat shields and post photos sometime soon.

I also found out that there's a hardness tester where he works, and another one where a friend works... Holy crap! I'll have to get a Rockwell number for EVERY COMPONENT OF THE CAR!

When I had my axle components, diff components and final drive gears treated, the shop gave me Rockwell numbers for some components but not all. The problem is that they drew back the diff side gears to a good hardness for drag racing. This make the gears slightly softer than they should be relative to the side plates for my EP LSD. However, the shop did not test (or did not give me numbers for) the side plates... so I'll need to test those.

Also, in all the discussions I've had about properly honing the Northstar bore liners, I've NEVER heard any Rockwell numbers... so I'm going to cut up an extra block I have and get some numbers from one of the liners.

Re: The Mule rides again (sort of) - pics.

Posted: Sat Jan 18, 2014 3:22 pm

by The Dark Side of Will

This happened a couple of weeks ago on my way back from the bank:

I eased out from a stoplight until the clutch was hooked up then punched it and had a free rev... I had enough momentum to make it to a parking lot. Came back later and brought it home on a rope. My dad was able to raid the stash and send me another tripod assembly.

The cup I broke at the dragstrip and this tripod were both in the car for the 1.5 years I daily drove it in P'Cola, so this is most likely the result of long term accumulation of overstress.

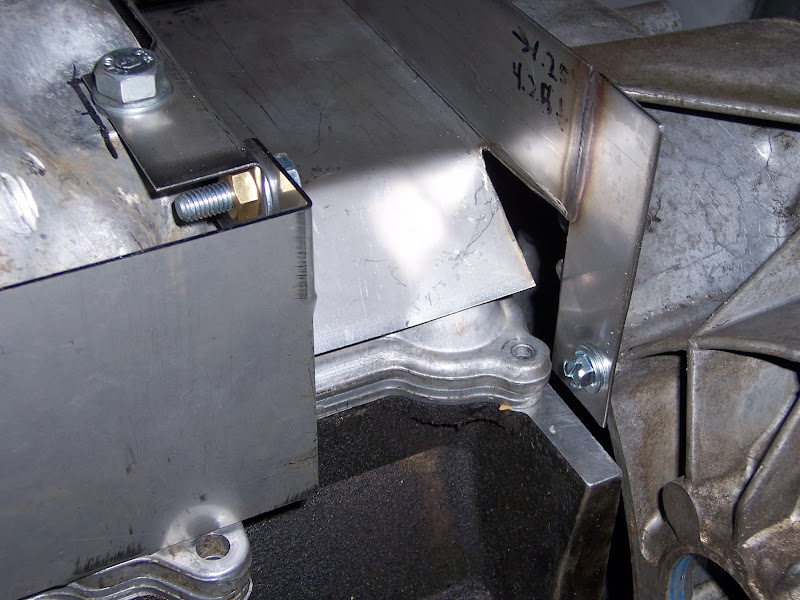

Also, finally got my heat shields done:

I'm not sure if the bolt that holds the two pieces together will clear the exhaust or not. If not, I'll replace it with a great big pop rivet or similar.

There's about 1/16" between the under-pan heat shield and the pan and about 1/16" between the heat shield and the pipe. I was testing it in the car before I decided I needed to make the rear face heat shield that would interface to it.

Re: The Mule rides again (sort of) - pics.

Posted: Sat Jan 18, 2014 3:28 pm

by ericjon262

I like the heat shield, only thing I would do is radius the corners a bit.

Re: The Mule rides again (sort of) - pics.

Posted: Sat Jan 18, 2014 3:48 pm

by The Dark Side of Will

Cell phone photo of rear face heat shield pre-bending:

I'll probably trim them a bit when I do my next round of engine-out mods... More worried about getting them to bolt up and play nice this time around.

The rear face heat shield is easy enough to make that I may just change the drawing and have a new one cut.

Re: The Mule rides again (sort of) - pics.

Posted: Sat Jan 18, 2014 4:00 pm

by ericjon262

been there done that, gotta start with a prototype and fix it from there...

Re: The Mule rides again (sort of) - pics.

Posted: Mon Jan 20, 2014 5:38 am

by The Dark Side of Will

Couple more shots of the heat shields:

Re: The Mule rides again (sort of) - pics.

Posted: Fri Feb 07, 2014 3:57 pm

by The Dark Side of Will

I have an extra crank shaft. I've already turned the counterweights like what I did on the crank that's currently in the engine. I was starting to get really evil thoughts about drilling the main and rod journals.

Drilling the rod journals or crank pins doubly lightens the crank and reduces engine speed rotating mass. In addition to the mass removed from the drilled hole, additional mass must be removed from the counterweight in order to keep the crankshaft balanced. Since both of these masses are close to the outside diameter of the crankshaft, they both contribute significantly to the moment of inertia of the crank. So a crank with drilled pins and reduced counterweights will spin up more quickly than an equivalent crank without prior to those operations.

Drilling the main journals is simple weight reduction. Because the mass removed is on the crank axis of rotation, it hardly contributes anything to the crank's moment of inertia. However, the hole through the main can add bay-to-bay breathing capacity to the crankcase and show a reduction in high RPM windage losses.

However, I investigated the crankshaft oil drillings and found that I can't do this with the crank's current oiling system.

I found that the oil holes are 6mm... a .234 gauge pin slipped in all the holes, but a .235 was hit-or-miss. That's slightly undersized for a 6mm hole, but the drill bit may have been worn.

If the Northstar had oil holes like these:

Teutonic wrote:

Simplified Moldex crank drilling:

Then I could drill the pins and mains.

Buuut... it doesn't. The Northstar's oil holes aren't quite that nice. However, they're worlds better than the stock Porsche oil holes also shown in the thread from which the above photo was taken:

http://www.corner-carvers.com/forums/sh ... hp?t=40328

That's a $20K+ build of a 6.5 liter bored and stroked Porsche 928 V8. Street tune with headers is about 450 to the wheels, but with a racing intake manifold that gives more top-end biased power delivery, it can top 500. IIRC it makes about 400 in CA emissions trim through stock exhaust manifolds.

I found from that thread that the Northstar borrows the cleverer oiling system ideas from the Porsche 928 engine, while ditching the bad design features (like the crankshaft oiling) that make the 928 engines blow up. A lot of people blindly repeat that the Northstar is 2 Quad 4's, and it DOES share the Q4's bore and stroke, but its internal layout is strikingly similar to that of the Porsche engine, much more so than it is to the Q4.

So now I'm asking myself how much I want drilled pins and drilled mains... Can I tap the existing holes, install set screws with red loctite and drill Moldex-style oil holes?

I'm also considering using two sets of upper main bearings in order to have 360 degree grooved bearings. As I'm staying N/A and not going with huge boost, I don't think I need the bearing area in the lower halves. Because the Northstar's thrust bearing is only on the upper half of the #3 main, this would also give me a 360 degree thrust bearing, which would be nice to have when running a clutch like a Tilton with a 500# release load.